In the fast-paced world of electronics manufacturing, precision and efficiency achieved through advanced vision inspection are not just goals; they are imperatives. As technology evolves, so does the complexity of electronic components, necessitating a level of precision that traditional manual inspections and older automated systems struggle to achieve. Introducing collaborative robots, commonly known as cobots, equipped with cutting-edge vision inspection capabilities that promise to transform the landscape of electronics manufacturing.

Introduction to Vision Inspections in Cobots

Vision inspection is a critical technological advancement in this sector, leveraging high-resolution cameras and sophisticated image processing software to detect defects and ensure component quality at unprecedented speeds. Cobots, designed to work alongside human operators, integrate these vision systems seamlessly. This synergy not only enhances the accuracy of inspections but also significantly boosts the efficiency of the production line.

This article will explore how cobots equipped with vision inspection technology are setting new standards in the electronics manufacturing industry, making them an invaluable asset for any company looking to thrive in this competitive market.

The Critical Role of Vision Inspection in Electronics

In electronics manufacturing, where the smallest imperfection can lead to system failures, the stakes for accuracy and reliability are sky-high. Vision inspection involves the use of cameras and sensors to analyze electronic components in real time, detecting anomalies and defects that might be invisible to the human eye. This method is pivotal for maintaining the high-quality standards that consumers and regulatory bodies demand.

The integration of vision inspection systems ensures that each component meets stringent quality control criteria, which is essential in sectors such as consumer electronics, automotive, and medical devices. These systems provide detailed reports that help manufacturers adjust their processes in real time, enhancing product reliability and reducing the risk of costly recalls or customer dissatisfaction.

Applications of Vision Inspection in the Electronics Industry

Vision inspection technology has become indispensable in the electronics industry due to its ability to enhance quality control, increase efficiency, and reduce costs. Here are five common areas where vision inspection is extensively applied:

-

Printed Circuit Board (PCB) Inspection

- Vision inspection systems are crucial in examining printed circuit boards, which are foundational to most electronic devices. These systems check for solder paste, component placement, and potential defects like misalignments or missing components. This ensures that each PCB meets strict quality standards before proceeding to the next stage of manufacturing.

-

Semiconductor Wafer Processing

- In semiconductor manufacturing, vision inspection is used to detect defects during the wafer fabrication process. It inspects the surface and structure of wafers at various production stages, identifying imperfections such as cracks, scratches, and foreign particles. This precision helps in maintaining the integrity of semiconductor devices.

-

Connector and Terminal Inspection

- Connectors and terminals are vital for the electrical and mechanical reliability of electronic devices. Vision inspection systems scrutinize these components for proper shape, size, and placement, ensuring robust connections and functionality across various applications.

-

Component Measurement and Placement

- Accurate component placement is critical for device functionality, especially in complex electronics. Vision inspection helps in measuring and verifying the position of components on an assembly line, adjusting placements in real time to avoid errors that could lead to device failures.

-

Final Assembly Verification

- Before electronic devices reach the market, they undergo final assembly verification to ensure all parts are correctly installed and functioning. Vision inspection plays a key role in this final quality assurance step, checking for complete assemblies, labeling accuracy, and packaging integrity.

Each of these applications highlights the versatility and essential nature of vision inspection in maintaining high standards within the electronics manufacturing industry.

Challenges of Traditional Vision Inspection Methods

Traditional vision inspection methods in the electronics industry face significant challenges that compromise their effectiveness. Reliance on manual inspections, which are slow and prone to human error, often leads to inconsistencies and missed defects. These methods struggle to match the rapid throughput demands of modern manufacturing, creating bottlenecks that can delay production and escalate costs.

Moreover, older automated systems lack the flexibility required to adapt to new or changing product lines. They are typically programmed for specific tasks and require extensive reprogramming for new specifications, leading to costly downtime. These systems also struggle with detecting subtle defects in high-precision components, risking product quality and potentially harming a manufacturer’s reputation due to increased failures and customer dissatisfaction.

The Advantages of Using Cobots for Vision Inspection

Collaborative robots, equipped with sophisticated vision systems, are transforming the landscape of electronics manufacturing by enhancing the precision and efficiency of inspection processes. Here are the key advantages:

- Advanced Imaging Capabilities: Cobots are equipped with high-resolution cameras and sophisticated imaging software for precise inspections.

- Increased Accuracy: AI-driven software allows cobots to detect minute discrepancies and defects, ensuring high-quality components.

- Flexibility in Production: Cobots can be easily reprogrammed to handle different electronic components and adapt to new production requirements, offering significant flexibility.

- Reduced Downtime: Quick task switching and minimal reprogramming needs help maintain continuous production flow with less downtime.

- Lower Maintenance Needs: Cobots are designed for continuous use with lower maintenance requirements compared to traditional automated systems.

- Operational Efficiency: Easy setup and integration into existing manufacturing lines enhance overall operational efficiency.

These points underscore the transformative impact cobots have on improving quality control, reducing operational errors, and increasing the adaptability of manufacturing processes.

Case Studies: Cobots in Action in Electronics Manufacturing

-

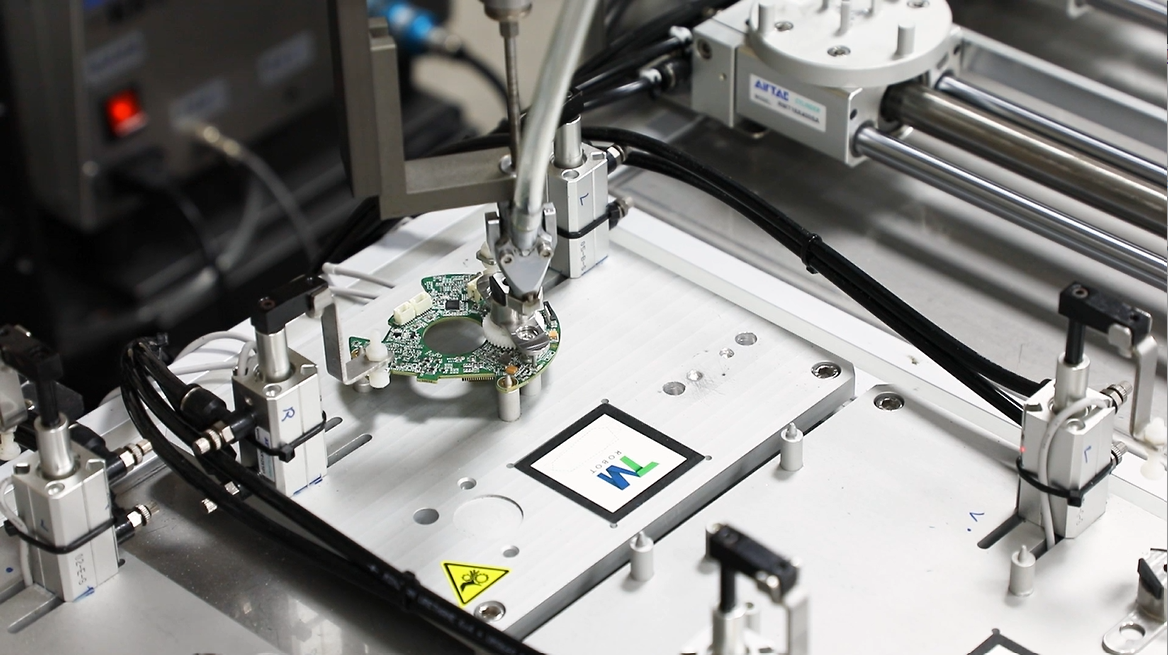

Automated Optical Inspection (AOI) in PCB Manufacturing

One of the standout applications of cobots in electronics manufacturing is their integration into the Automated Optical Inspection (AOI) systems used in PCB manufacturing. Techman Robots have been instrumental in enhancing the visual inspection of completed circuit boards. These cobots utilize high-resolution cameras and sophisticated computer vision algorithms to detect component alignment issues, missing components, and other potential defects on circuit boards. The tangible benefits include significantly increased accuracy in defect detection, which ensures that only PCBs that meet stringent quality standards advance in the production process. This leads to higher reliability of electronic devices and a reduction in costly manufacturing errors.

-

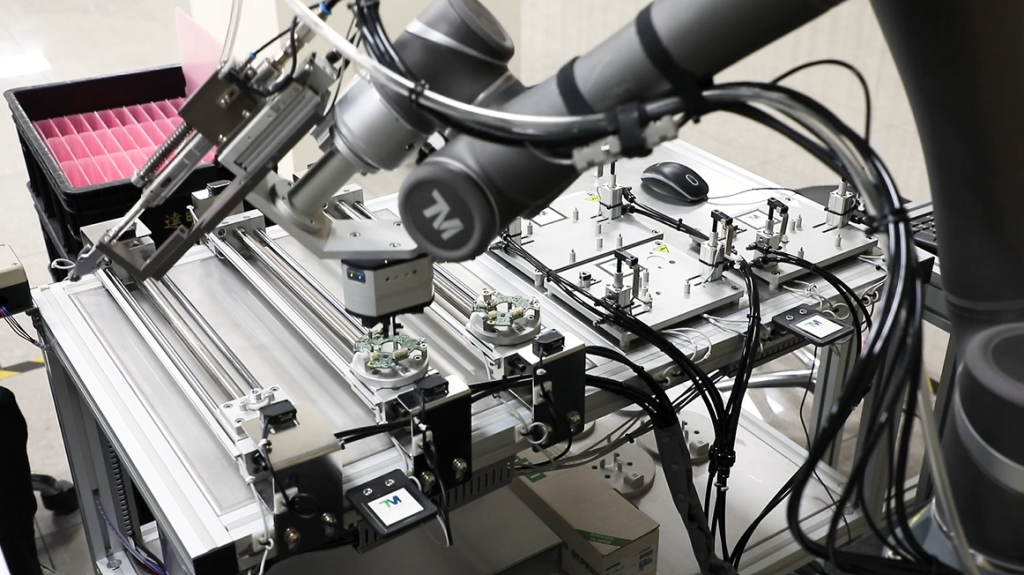

Cobots in Precision Electronics Assembly

Techman Robots significantly improve precision and efficiency in electronics assembly with their advanced vision systems. These cobots automate critical tasks such as component placement and quality inspections. Their ability to detect minute alignment errors ensures high-quality production standards. By reducing human error and speeding up processes, they not only enhance product reliability but also lower manufacturing costs. For further insights into Techman Robots’ applications in electronics assembly, visit the application video showcase page.

These examples underscore how cobots are transforming electronics manufacturing by bringing more precise, efficient, and cost-effective solutions to complex production challenges. Techman’s cobots not only streamline operations but also ensure that the electronics produced are of the highest quality, aligning with industry standards and consumer expectations. For more detailed insights, you can explore further on Techman’s website here.

Embracing the Future as Cobots Revolutionize Vision Inspection

Cobots equipped with vision inspection capabilities have revolutionized industries by enhancing precision, efficiency, and adaptability in quality control processes. These systems significantly reduce error rates, boost product reliability, and streamline workflows, reshaping production and quality assurance landscapes. As industries evolve, adopting such technological advancements becomes essential for staying competitive and scaling with future demands. Manufacturers are urged to integrate cobots into their operations to set new standards in operational excellence and maintain a cutting edge in high-quality production.

To learn more about how Techman Robot’s collaborative robots can transform your manufacturing operations, contact us here for a consultation.