Collaborative robots, or cobots, have emerged as game-changers across various industries, including manufacturing, automotive, healthcare, and logistics. Unlike traditional industrial robots that operate in isolated environments, cobots are designed to work alongside human workers, enhancing productivity and safety.

Addressing Automotive Manufacturing Problems with Collaborative Robots

In the dynamic field of automotive manufacturing, collaborative robots offer innovative solutions to persistent problems, enhancing efficiency, precision, and productivity. Here’s how cobots address key challenges in the industry:

Complex Inspection Tasks and Diverse Product Variations

Automotive manufacturers handle a variety of product styles and face intricate inspection requirements that traditional methods often struggle to manage. Collaborative robots with advanced vision systems can easily adapt to these diverse tasks, ensuring thorough and accurate inspections across different components.

High Error Rates in Manual Inspections and Lack of Traceability

Manual inspections are prone to errors and lack of traceability, leading to missed defects and potential product damage. Collaborative robots provide consistent, accurate inspections and real-time data logging, reducing errors and improving quality control.

Challenging Inspection Angles Beyond the Reach of Fixed Cameras

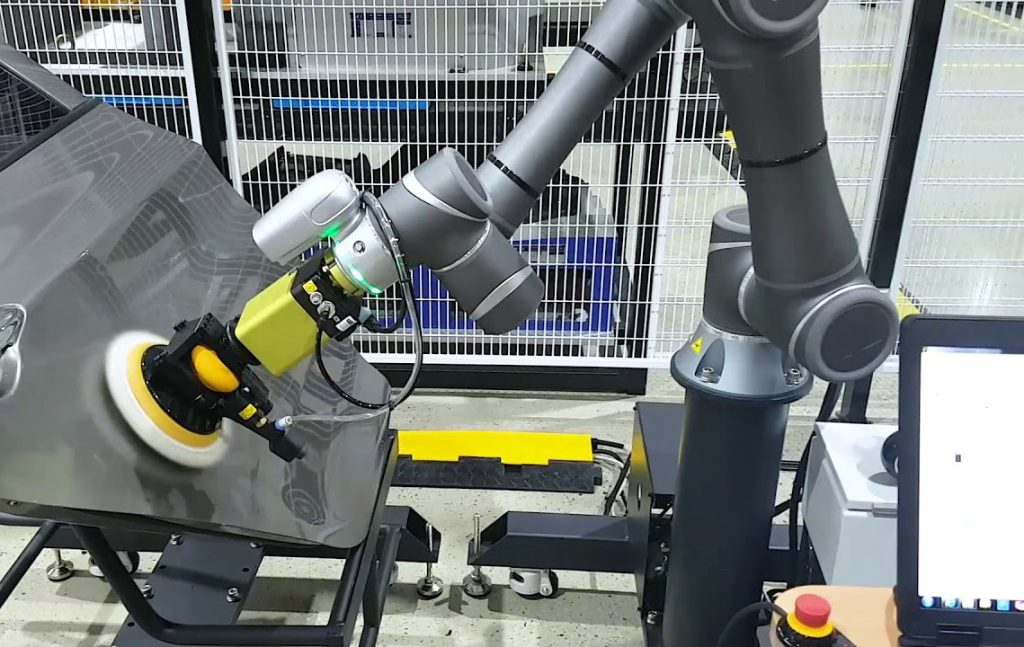

Some inspections require angles difficult for fixed cameras. Collaborative robots with articulated arms and movable cameras can reach tight spaces and capture comprehensive views, enhancing quality control and ensuring no defects are overlooked.

In summary, collaborative robots effectively tackle complex inspections, reduce error rates, improve traceability, and navigate challenging inspection angles, significantly enhancing manufacturing efficiency and quality.

Benefits of Collaborative Robots in the Automotive Industry

There are at least 5 benefits of using collaborative robots in the automotive industry:

- Enhanced Safety: Automotive cobots are designed with advanced sensors and safety features that allow them to work alongside human workers without causing harm. This reduces workplace accidents and ensures a safer manufacturing environment.

- Increased Productivity: By operating continuously without breaks, automotive cobots significantly boost productivity. They handle repetitive and precise tasks efficiently, reducing production time and increasing overall output.

- Flexibility and Adaptability: Collaborative robots are easily programmable for the automotive industry and can be quickly reconfigured for various tasks, which is crucial in the automotive industry where production lines need frequent adjustments for new models or customizations.

- Cost-Effectiveness: Automotive cobots reduce labor costs by taking over repetitive tasks and minimizing errors, leading to lower production costs. Their precision also reduces waste and rework, enhancing overall cost savings.

- Precision and Consistency: Collaborative robots offer high levels of precision and consistency, essential for tasks like assembly, welding, and painting. Their ability to perform these tasks with minimal errors ensures high-quality production.

These features make collaborative robots particularly suitable for the automotive manufacturing industry where they can handle a variety of tasks, from assembly line automation to quality control and material handling.

Finding the Right Collaborative Robots for the Automotive Industry

Choosing the right collaborative robot (cobot) is essential for optimizing automotive manufacturing processes. Here are the key features to consider:

- Payload Capacity: Ensure the cobot has a high payload capacity to handle heavy components like engine parts and body panels, allowing it to manage a wide range of tasks without overloading.

- Precision and Accuracy: Look for cobots with high precision capabilities for tasks such as assembly, welding, and painting. This ensures consistent and error-free performance, maintaining high production quality.

- Advanced Vision Systems: Cobots with advanced vision systems can perform detailed inspections and quality control checks, crucial for identifying defects and ensuring all components meet stringent quality standards.

- Ease of Programming and Flexibility: A user-friendly interface and versatile programming options are vital for quick adjustments and minimal downtime, allowing the cobot to adapt to frequently changing production lines.

- Safety Features: Advanced safety features, such as collision detection and automatic stop functions, are essential for ensuring a safe working environment for human workers.

- Integration Capabilities: The cobot should seamlessly integrate with existing manufacturing systems and equipment, ensuring compatibility with various software and hardware for smooth operation and coordination.

Success Story: Enhancing Automotive Manufacturing with TM AI Cobots

Client Background

A renowned brand manufacturer in the automotive industry sought to enhance their production line’s efficiency and accuracy. They aimed to improve the examination of automobile appearance, engine components, and interior spaces, ensuring high-quality assembly and reducing error rates.

Automation Solution

The manufacturer implemented an advanced solution using cobot arms and cameras integrated with an AI system. This system was designed to inspect various parts of the automobiles, including the exterior, engine, and interior spaces.

Implementation Details

- AI System: Utilized AI classification with a dataset of 50 images for each inspection item. Model training for each item took only 20 minutes.

- Cobots and Cameras: Four cobots, supported by over 30 external cameras, performed simultaneous assembly checks.

- Performance: More than 120 vision tasks were completed within 80 seconds, with inspection items synchronized to the client’s shop floor system.

Results

This integration allowed for thorough and rapid inspection processes, significantly enhancing the accuracy and efficiency of the production line. The AI system confirmed all assembly parts and recorded examination results along with image data in a centralized database, ensuring traceability and quality control.

Future Trends of Collaborative Robots in Automotive Industry

As the automotive industry continues to embrace automation, collaborative robots are poised to undergo significant advancements that will revolutionize manufacturing processes. Here’s a look at some of the key trends and innovations shaping the future of cobot technology:

1. AI-Powered Vision Systems: Redefining Precision and Efficiency

In automotive manufacturing, collaborative robots drive innovation with advanced AI and machine learning capabilities. Central to their impact are AI-powered vision systems integrated into operations, empowering cobots to process and analyze visual data in real-time. This revolutionizes critical tasks like quality control and product inspection with unparalleled accuracy. AI also enables cobots to dynamically adjust operations, enhancing productivity and workplace safety by reducing human errors and hazards. This integration underscores cobots’ role in maintaining production standards and prioritizing worker safety in dynamic manufacturing environments.

2. Enhanced Sensor Technology: Expanding Perception Capabilities

Cobots are increasingly integrating advanced sensor technology to expand their perception capabilities. Let’s explore the latest advancements in sensor technology for future automotive cobots. These advancements include AI-driven vision systems for high-resolution imaging and object recognition, tactile sensors for precise handling, and force/torque sensors to enhance assembly operations. Environmental sensors such as lidar and radar enable cobots to navigate safely around obstacles, thereby improving both production efficiency and workplace safety through reliable interactions with human operators.

3. Cloud-Enabled AI Vision: Driving Manufacturing Intelligence

The integration of cobots with the Internet of Things (IoT) and cloud computing represents a pivotal advancement in manufacturing intelligence. At the heart of this evolution lies cloud-enabled AI vision, where data captured by cobots’ AI vision systems is seamlessly transmitted and processed in the cloud. This integration leverages IoT connectivity to deliver real-time insights and predictive analytics, empowering automotive manufacturers with agile decision-making capabilities. By scaling operations efficiently and embracing cloud computing, manufacturers ensure that cobots equipped with AI vision remain catalysts for innovation in smart manufacturing initiatives.

Conclusion

Collaborative robots are transforming the automotive industry by enhancing efficiency, precision, and productivity. Cobots from Techman Robot tackle complex inspections, reduce error rates, and handle challenging angles, offering invaluable solutions. Integrating these cobots can significantly improve your production processes and maintain a competitive edge.

To learn more about how Techman Robot’s collaborative robots can transform your manufacturing operations, contact us for a free consultation.