Examples are valid for:

TMflow Software version: 2.18 or above.

TM Robot Hardware version: HW3.2 or above

Other specific requirements: None

Note that older or newer software versions may have different results.

TMflow offers a wide range of features designed to enhance the efficiency of automation operations. In factories, the status of each machine is usually obtained by connecting to a host computer. The TMcraft Toolbar provides users with the convenience of being able to monitor relevant information according to their own needs and quickly set up Modbus storage locations on different robots, greatly simplifying the configuration process and further enhancing the flexibility and efficiency of the system.

Purpose of Using the TMcraft Toolbar #

- Get Robot Status : Obtain various types of robot messages and variables according to requirements.This allows users to create concise and diverse user interfaces (UI) to meet the needs of different application scenarios.

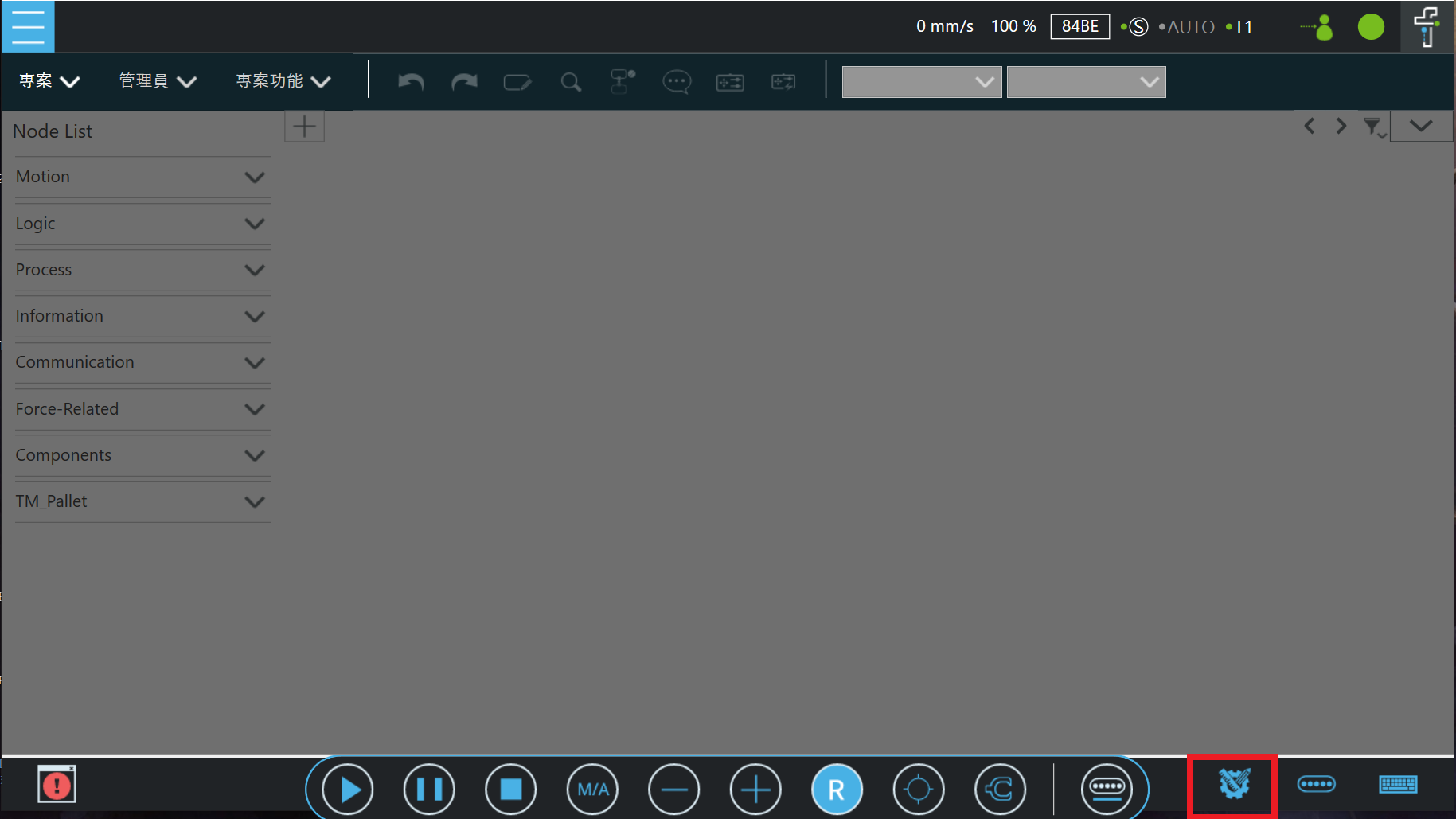

- Project-independent:Users can enable the Toolbar through the lower right corner of the TMFlow interface, and its functionality does not depend on a specific project. Not only can the Toolbar be used in different projects, but the Toolbar can also run smoothly even if no project is open.

Application Scenarios #

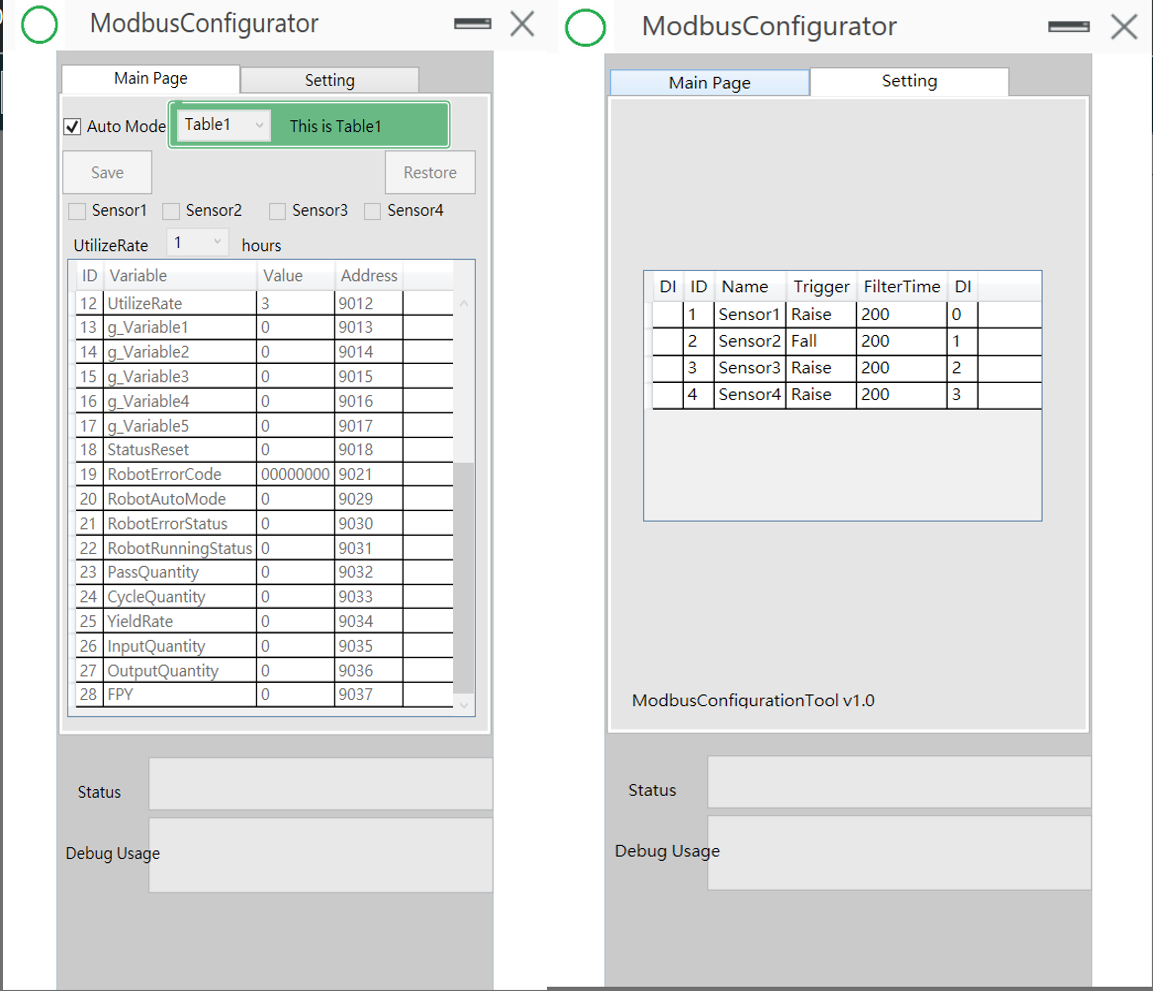

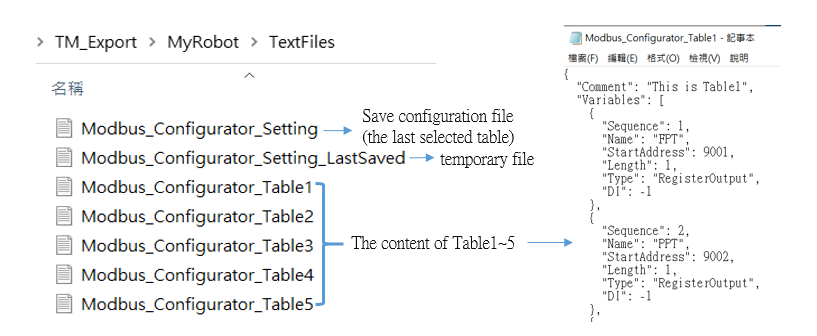

In a factory where multiple robot need to upload various information to the host computer via Modbus, accessing each arm’s project one by one to configure the settings can be time consuming and labor intensive. To solve this problem, the TMcraft Toolbar API can be used to quickly obtain the required arm data or variables and store the data in the Modbus customization area (9000-9999). After finishing the programming, import the program and setup files (TextFiles for Table1~5 settings) into TMFlow.When TMFlow is opened, user just need to click the TMcraft Toolbar icon on the bottom right corner, set the Modbus and sensor position, and then check “Auto Mode” to start running the program. The system will continuously write relevant information, enabling the host system to retrieve arm data in real time.

If you want to get started quickly and learn how to customize the interface for your project needs, please refer to the sample code.

Functionality #

- Auto : All operable areas are locked.

- Table : 5 kinds of setting files can be switched. (5 Modbus storage locations + sensor DI location)

- Main Page:Display the address of each parameter (can be modified by yourself) and its value, whether the sensor is triggered or not.

- Setting:Shows the position of the 4 sensors in the control box DI. (can be modified by yourself)

- UtilizeRate : Self-adjustable 1~24 hours

Description (Using the robot’s Manual/Auto status as an example.) #

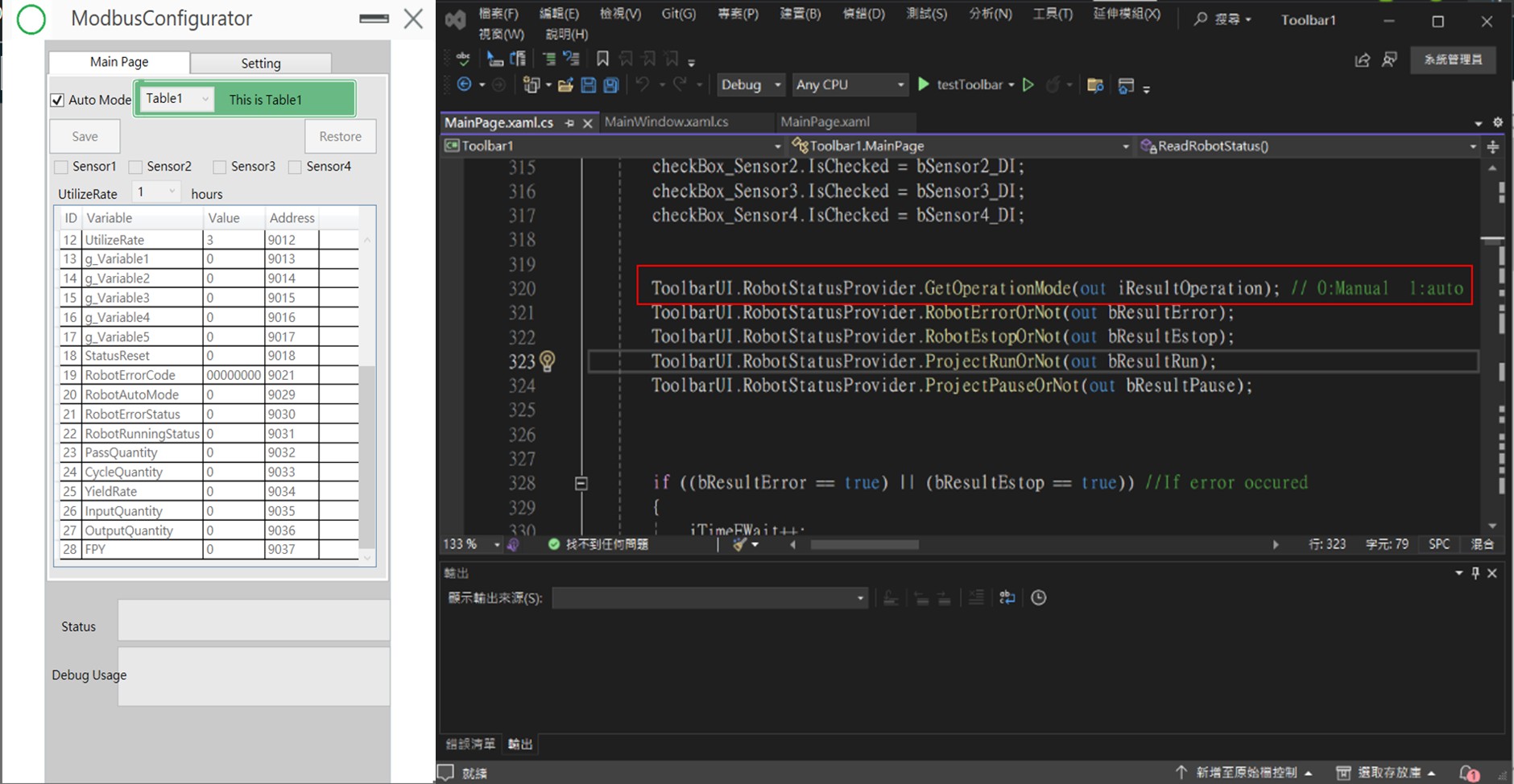

- Programming with Visual Studio

- Reference to the TMcraft Toolbar API

- Get the robot status (ex: manual/automatic mode, occurrence of erros, etc).