The advent of collaborative robots, or “cobots in manufacturing,” signals a transformative shift toward more intelligent and adaptable processes within the industry. Unlike traditional robotics, “manufacturing cobots” are engineered to collaborate seamlessly with human operators, boosting productivity while enhancing safety and adaptability.

Introduction to Cobots in Manufacturing Trends

As we venture into the future of factory automation, we will explore how “manufacturing cobots ” are pivotal partners in redefining industry standards, particularly in quality assurance and operational flexibility.

The role of cobots in manufacturing is diversifying rapidly, expanding from simple assembly functions to sophisticated tasks such as quality control, materials handling, and precise assembly operations. This broadening scope is facilitated by recent advances in artificial intelligence and machine learning, which empower cobots with greater autonomy and enhanced decision-making capabilities.

Cobots in Manufacturing and Quality Assurance

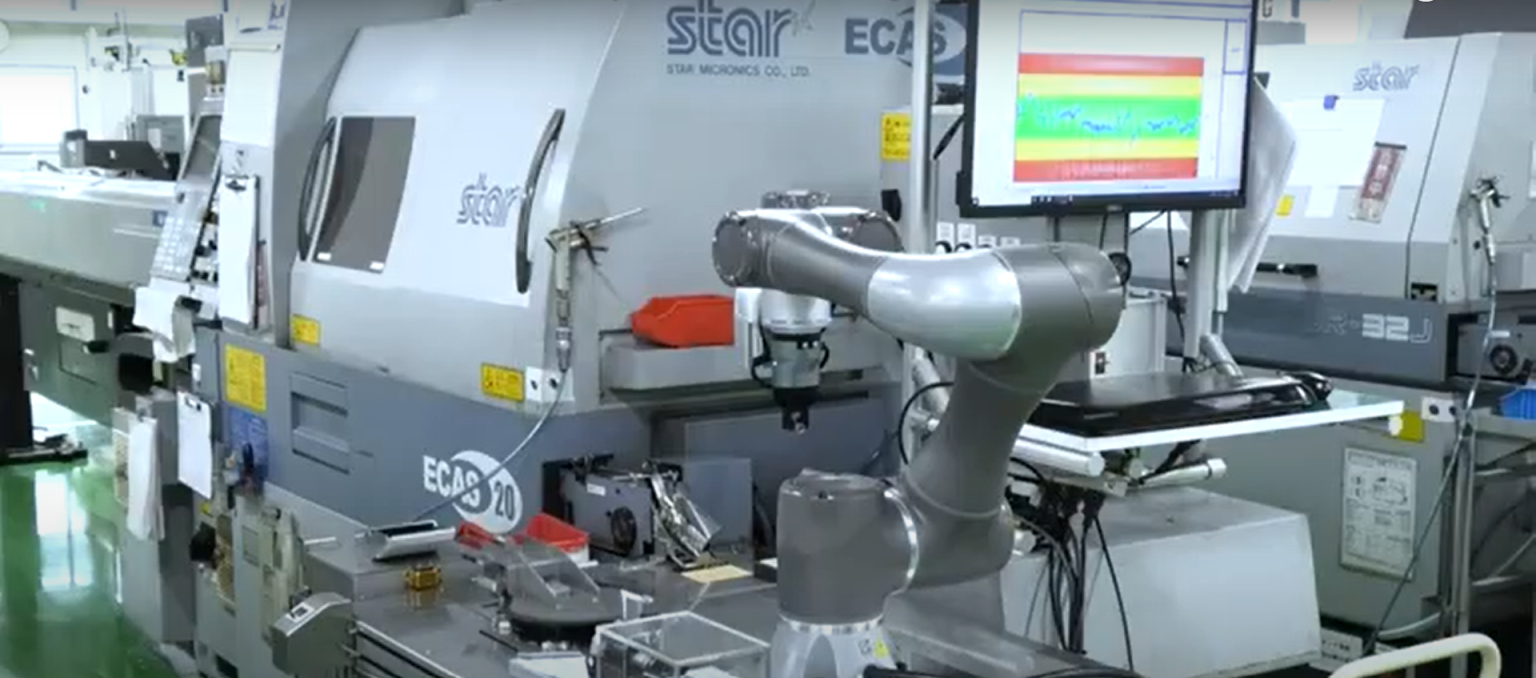

As manufacturing industries strive for higher efficiency and flawless product quality, manufacturing cobots have become instrumental in transforming quality assurance protocols. These collaborative robots integrate seamlessly with human teams to ensure precision and reliability in production lines.

Consistency and Precision

Manufacturing cobots bring a new level of consistency to quality assurance tasks in manufacturing. Equipped with advanced vision systems and sensors, they can perform intricate inspections that are beyond the scope of human capability. This includes checking for minute defects or inconsistencies in products, and ensuring every item adheres to stringent quality standards.

Speed and Real-time Data Utilization

Implementing manufacturing cobots in quality assurance not only bolsters accuracy but also accelerates the inspection process. This increase in speed does not compromise quality; instead, it allows for real-time data collection and analysis. Manufacturing cobots can instantly feed inspection data back into production systems, enabling dynamic adjustments and continuous improvement. This real-time processing helps identify and rectify potential issues swiftly, minimizing downtime and waste.

Flexible Integration

The adaptability of manufacturing cobots makes them ideal for a variety of manufacturing environments. They can be easily programmed to handle different products or adjust to new quality standards, making them valuable for industries that require high flexibility in their operations. This versatility ensures that manufacturers can maintain high-quality output even as product designs and components evolve.

The Role of Vision-Equipped Cobots in Manufacturing

Cobot vision systems are revolutionizing the way quality control is conducted in manufacturing, providing significant enhancements in both precision and operational speed.

Enhanced Consistency and Precision

The implementation of manufacturing cobots equipped with advanced vision systems has transformed quality control protocols in manufacturing inspections. These cobots, using high-resolution cameras and precise sensors, provide a level of consistency unattainable by human inspectors, significantly reducing errors and variability in production lines. They can detect defects and discrepancies with exceptional accuracy, minimizing costly recalls and enhancing customer satisfaction.

Maximizing Speed and Volume Production

Cobot vision systems enhance both the speed and efficiency of manufacturing operations. They process visual data rapidly, inspecting parts faster than human workers and supporting quicker production cycles without sacrificing quality. This is crucial for industries where reducing time-to-market is essential. Manufacturing cobots also integrate inspection data into production workflows in real time, allowing for on-the-fly adjustments and minimizing error propagation. This capability is particularly advantageous in high-volume production environments, where it ensures continuous operation and maximizes the output of high-quality products.

Manufacturing Cobots Drive Flexibility in Modern Production

As manufacturing processes become increasingly complex and customized, the need for flexible automation solutions has become paramount. Manufacturing cobots, with their advanced capabilities, are at the forefront of this shift, offering adaptable solutions that enhance both productivity and agility in modern manufacturing environments.

Modularity and Reconfigurability

Designed for modularity, cobots in manufacturing process can easily switch end-effectors like grippers and welders, allowing them to handle various tasks from assembly to inspection. This versatility reduces the need for multiple specialized machines and cuts setup times. Manufacturers can quickly adapt these cobots to new products or volume changes, maintaining a flexible and responsive production environment.

Seamless Integration into Existing Production Lines

A key advantage of cobots in manufacturing is their seamless integration into existing setups without extensive modifications. Unlike traditional industrial robots that require dedicated spaces, cobots can be easily deployed alongside human workers, enabling quick adjustments and reducing downtime. Their user-friendly interfaces also simplify operations, enhancing flexibility within the manufacturing process.

Digital Traceability for Cobots in Manufacturing

As the manufacturing industry moves towards more digitized and traceable processes, cobots play a crucial role in this transformation. By integrating advanced technologies, cobots enhance the ability to monitor and document every aspect of the manufacturing process.

Enhancing Data Accuracy and Accessibility

Equipped with sensors and connectivity, manufacturing cobots can relay critical real-time data, from production counts to quality inspection results, directly into digital traceability systems. This automation minimizes human error and enhances accuracy, making data more reliable and accessible for quick, informed decision-making in manufacturing.

Streamlining Compliance and Quality Control

The integration of cobots into manufacturing lines significantly aids in compliance with regulatory standards and enhances quality control processes. These robots execute precise, repetitive tasks with consistent output, automatically recorded into traceability systems. This documentation is vital for industries like pharmaceuticals and automotive manufacturing, which demand strict quality and safety adherence. Cobots provide detailed audit trails, simplifying compliance and enhancing productivity and transparency.

Advanced Production: Implementing Cobots in Manufacturing

Implementing cobots in manufacturing workflows involves several key steps to ensure they add value and enhance productivity:

- Assessment and Planning: The first step involves assessing the existing processes to identify areas where cobots can be most effective. This includes analyzing tasks for their potential for automation and planning the integration in a way that complements human labor.

- Choosing the Right Cobot: Depending on the specific needs—such as payload capacity, reach, and precision—selecting the appropriate cobot is crucial. Different models offer various capabilities that can suit tasks ranging from simple material handling to complex assembly.

- Setup and Integration: Implementing cobots typically requires less time and fewer structural changes than traditional robots. However, proper setup is crucial, which includes configuring the cobot, installing necessary safety measures, and integrating it with existing machinery and control systems.

- Training and Onboarding: Training staff to work alongside cobots is essential. This training not only covers operational procedures but also safety practices to ensure a collaborative environment where humans and robots work effectively together.

- Monitoring and Optimization: Once cobots are in place, continuous monitoring helps in optimizing their performance and identifying further areas for automation. This iterative process helps refine the integration of cobots and expand their use as technology advances and production needs evolve.

By following these steps, businesses can effectively implement manufacturing cobots, leading to increased efficiency, reduced costs, and improved worker safety.

Conclusion

The role of cobots in manufacturing is poised for significant expansion, enhancing processes, and sparking innovations. Already vital for increasing efficiency, ensuring quality, and complying with standards, the potential of manufacturing cobots extends well beyond these achievements. As technologies evolve, cobots are set to handle increasingly complex tasks, fostering deeper collaboration with human operators and driving customized production.

The shift towards sustainable manufacturing practices also sees cobots playing a crucial role. By optimizing energy use and minimizing waste, they are central to industry efforts to reduce environmental impacts.

To learn more about how Techman Robot’s collaborative robots can transform your manufacturing operations, visit our website or contact us for a consultation.