Client:

A leading printing company in Taiwan that focuses on delivering high-quality custom printing solutions for a wide range of products.

Application:

Automated visual inspection for printed fan products.

Challenge:

The printing company faced critical assessment challenges in their production line, particularly for inspecting printed fans. While their loading and unloading processes are semi-automatic, inspection still remains a manual task, leading to inefficiencies in quality control. The primary issues included:

- Inconsistent Manual Inspection: The existing inspection process relied on human inspectors, making it difficult to detect minor deviations and ambiguous defects. The manual process was both time-consuming and challenging since human inspectors are prone to fatigue. As a result, non-conforming products occasionally slipped through, leading to customer complaints and negatively affecting brand reputation and production quality.

- Defective Adhesive and Misalignment: Printed materials on the fans occasionally failed to adhere correctly or were misaligned, resulting in defects.

Solution:

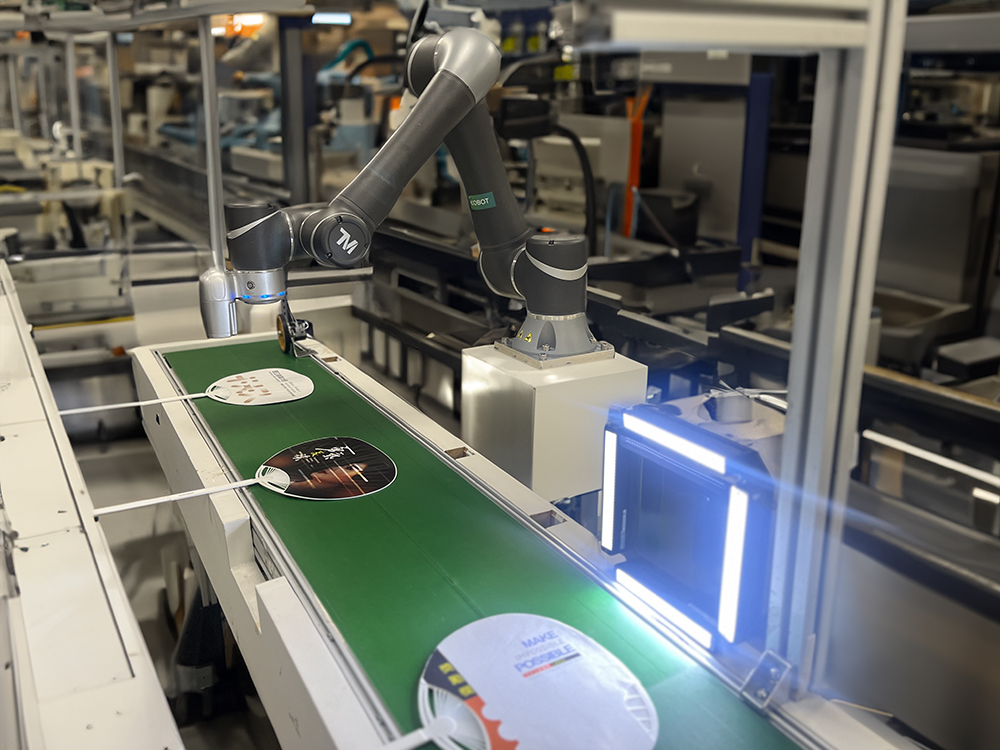

To overcome these challenges, TM AI Cobot was introduced to perform an AI-powered visual inspection solution using the TM5-900 cobot model. This setup was designed to automate and enhance the accuracy of the inspection process.

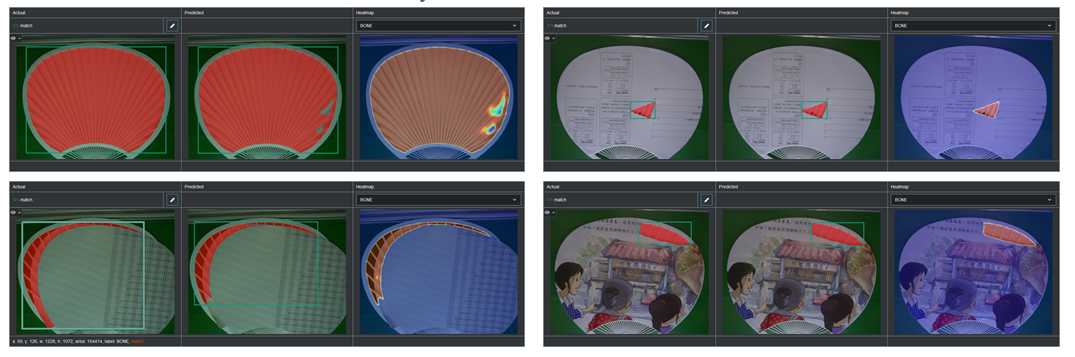

AI-Enhanced Visual Inspection for Printed Fans

The solution utilized the cobot combined with a semantic segmentation function to ensure precise identification of defects. The system worked as follows:

- Automated Inspection Process: Fans were placed on a conveyor, where sensors triggered a camera to capture images for AI-based analysis. The circular light beside the fan ensured optimal lighting conditions, enabling the system to accurately detect defects such as adhesive failures or misalignment.

- Efficient Detection and Filtering: Using AI inspection, efficiency was increased by 5 times with a 100% recall rate. False positives were minimized through a filtering mechanism based on area and score thresholds, ensuring accurate and reliable defect detection.

- Consistent and Fast Processing: Each fan was inspected in approximately 0.5 seconds, maintaining a consistent cycle time and improving overall efficiency.

Results:

The deployment of Techman Robot’s AI visual inspection solution led to substantial improvements for the client. Key benefits included:

- Increased Inspection Accuracy: The precision and recall rates ensured that all defective products were effectively identified, reducing the chances of flawed items reaching customers.

- Enhanced Operational Efficiency: Automating the inspection process allowed for a consistent cycle time of 0.5 seconds per fan, streamlining quality control and minimizing the need for manual labor.

- Improved Brand Reputation: By reducing defects and maintaining high product quality, the client was able to enhance customer satisfaction and protect its brand reputation.

Through this collaboration, the printing company successfully addressed its quality control challenges, setting a benchmark for efficient and reliable inspection solutions in the printing industry.