Background and Customer Needs

In the fast-paced world of electronics manufacturing, ensuring the quality of products before packaging is critical. A major customer required a solution to detect damaged or missing parts on printed circuit boards (PCBs) with high accuracy and efficiency. Manual inspection methods struggled to keep up with production demands and often overlooked small defects.

Challenges

- Detection of Small Anomalies: Human inspectors found it challenging to consistently identify tiny defects on PCBs.

- High Volume Production: The need for rapid, scalable inspections to match production cycle times.

- Labor-Intensive Process: Dependence on manual inspections increased costs and introduced inconsistencies.

Solution & Key Technologies

Techman Robot’s TM AI Cobot provided a comprehensive automated solution, integrating advanced imaging and AI classification technology.

-

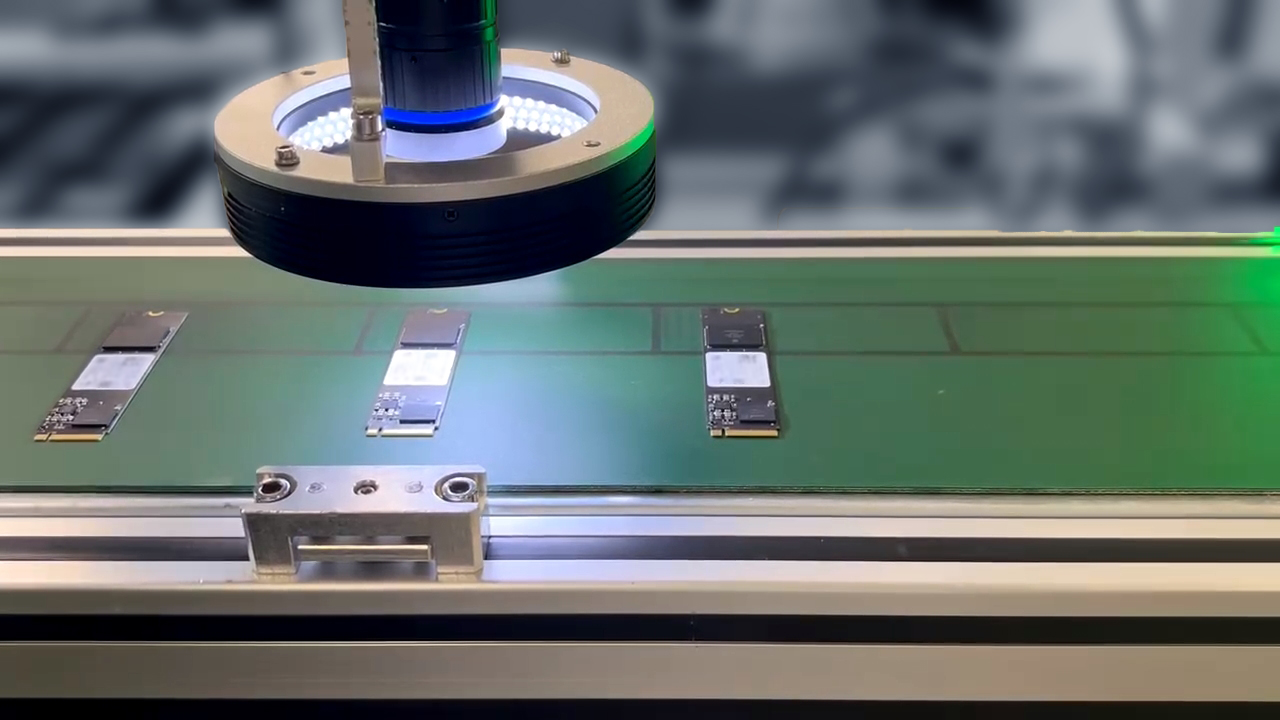

Imaging & Detection

- The Eye-in-Hand (EIH) camera enabled precise positioning and the external camera enabled multi-point visual inspection, performing image capture from multiple angles to ensure every component was inspected accurately.

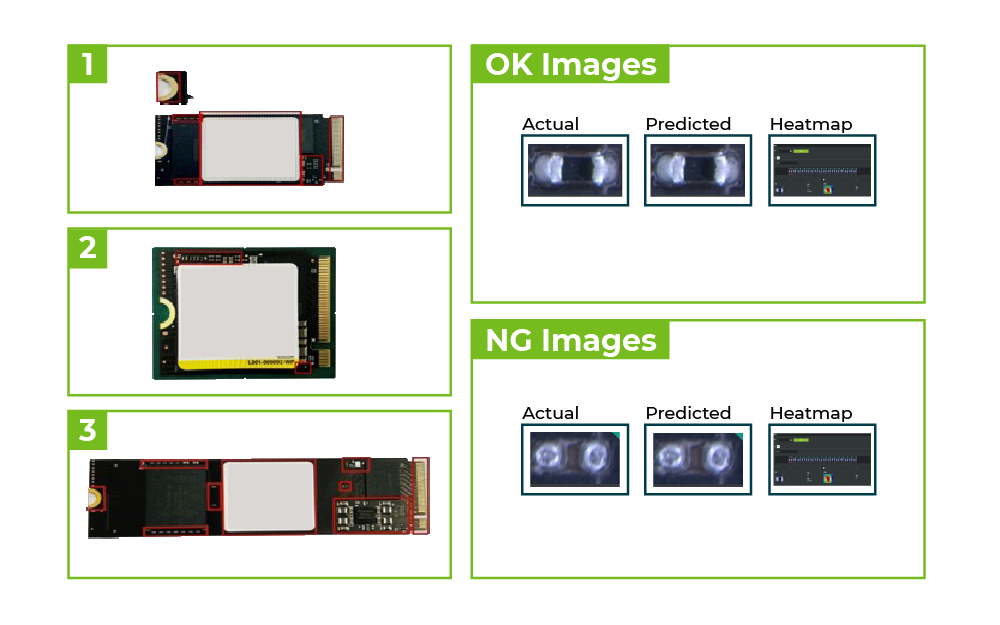

- Images were analyzed using the AI model to classify parts as Pass (OK) or Fail (NG).

-

AI Model Training

- Leveraged classification AI to train the system with a dataset of 70 images (40 OK, 30 NG).

- Training time was minimized to just 15 minutes, enabling quick adaptation to changes in production requirements.

-

Automated Workflow

- OK Products: Automatically directed to the next station.

- NG Products: Identified and the cobot arm will pick out the defective part to a dedicated cycle area for further process.

- Results were computed on the AOI Edge and then transmitted to the robot, which executes the decision-making to ensure a seamless production flow.

Application Scenarios

- Detecting missing or damaged parts before packaging

- Ensuring product quality by identifying small anomalies early in the process

Benefits

-

Enhanced Accuracy

- Achieved an inspection accuracy rate of 99.99%.

- False alarm and overkill rates were reduced to less than 1%, ensuring reliability.

-

Increased Efficiency

- Automation improved inspection speed and reduced manpower requirements by 50%.

- High-speed inspection aligned seamlessly with production cycle times.

-

Cost Reduction

- Lower reliance on manual labor minimized operational costs while enhancing consistency.

Conclusion

The part detection solution using TM AI Cobot demonstrates how smart automation transforms inspection processes. By combining AI-powered classification with precise vision technology, this case exemplifies how manufacturers can achieve unparalleled efficiency, accuracy, and cost savings in modern production lines.