Background and Customer Needs

Our client specializes in manufacturing high-quality speaker systems. In their speaker assembly lines—covering 8-inch, 12-inch, and 15-inch models—ensuring that every screw is securely fastened is essential for structural integrity and sound performance. However, the manual assembly process occasionally resulted in missing screws, leading to customer complaints, costly rework, and potential damage to the brand’s reputation.

The customer was looking for a solution that could:

- Eliminate screw fastening errors caused by human oversight

- Provide real-time quality assurance without slowing down the production line

- Be quickly trained and deployed to handle different speaker models

Challenges

Despite well-defined standard operating procedures, they encountered several key challenges on the production floor:

- Human Error: Manual inspections were inconsistent and prone to oversight, especially during high-volume production.

- Lack of Traceability: It was difficult to track whether each screw had been properly fastened in real time.

- Model Variability: Differences in screw locations and quantities across speaker sizes (8″, 12″, and 15″) made a one-size-fits-all inspection approach impractical.

These challenges highlighted the urgent need for a robust, automated inspection system that could guarantee 100% fastening verification with minimal setup time.

Solution

To resolve this issue, the speaker manufacturer implemented TM AI Cobot to automate screw fastening and AI inspection. This solution combines industrial vision with AI to automatically verify whether screws are fully secured during assembly.

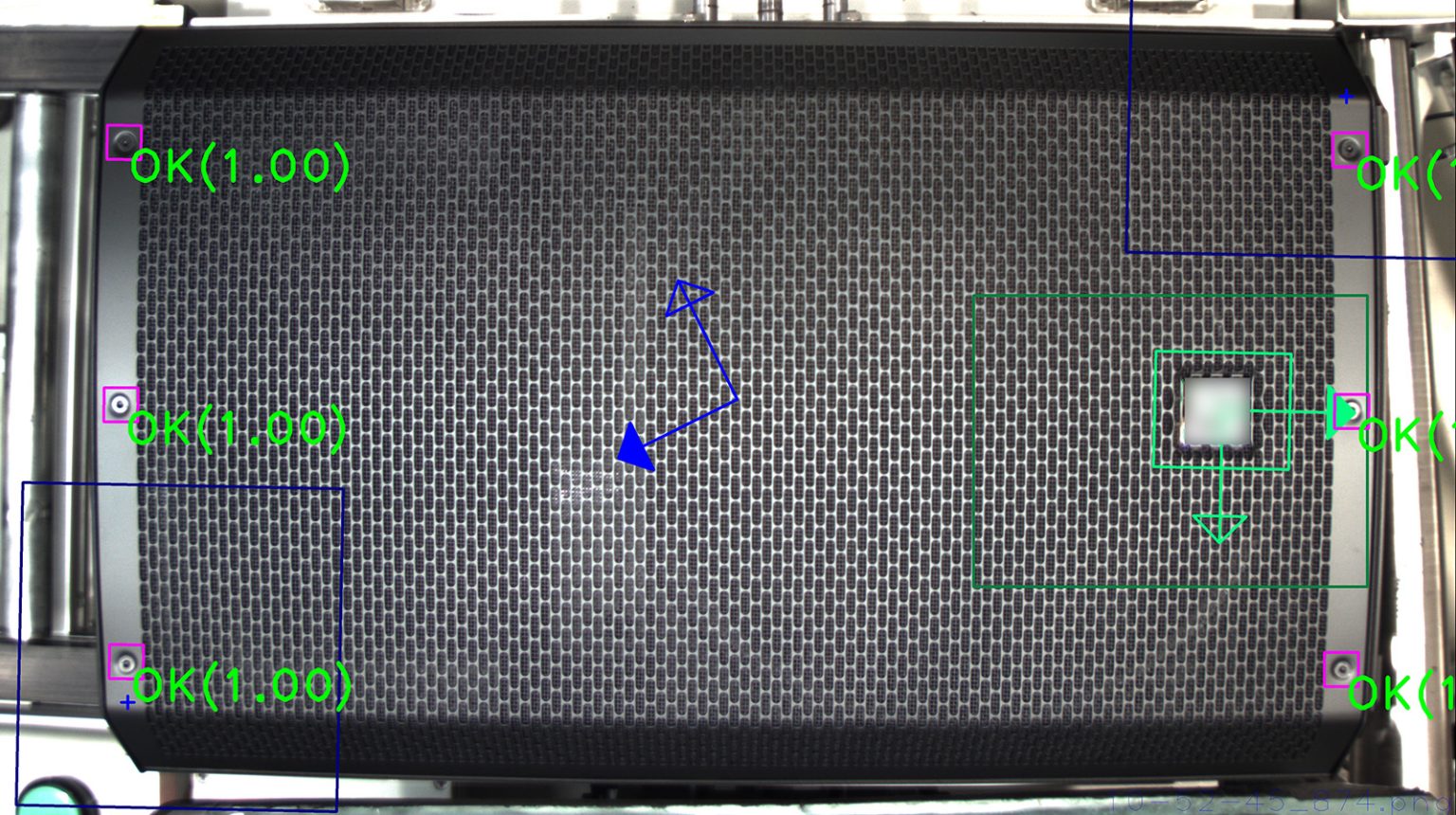

The inspection workflow starts with a Basler camera mounted above the assembly line, providing an ariel view of the speakers. This camera is integrated with a collaborative robot (cobot), so that once the screws are fastened, the cobot activates the Basler camera to capture an image. The images are analyzed using an AI model that detects and flags any missing or improperly fastened screws. If a non-conforming (NG) product is identified, an alert is automatically triggered to notify the operator.

AI Model Training

- Training Time: Approximately 3 minutes

- AI Function Used: AI Classification

- Dataset Size: 100 OK images, 67 NG images

- OK Products: Passed inspection and continued to the next production stage

- NG Products: Flagged for rework, preventing defective units from advancing in the process

Results & Benefits

- Minimized human error

- Real-time alerts and automated verification

- Fast AI model training with high accuracy

With the cobot solution in place, our customer significantly reduced customer complaints and rework caused by missing screws. The solution ensures product quality while streamlining the inspection process.