Client: A leading tier-1 manufacturer of consumer electronics

Application: Automated optical inspection for quality check

Challenge: Ensuring product quality is critical in the consumer electronics industry to manufacture home appliances. The client faced significant challenges in their manual inspection process, which included:

- Difficulty in detecting defects consistently due to varying inspection conditions.

- High labor costs associated with manual inspection.

- Inconsistent inspection results due to human error.

- There is a need for specific imaging conditions to make the feature good enough for AI inspection.

The client required a reliable, automated solution to enhance their quality inspection process, reduce errors, and improve overall productivity.

Solution: To address these challenges, the client implemented TM AI Cobot into their factory for automated optical inspection. The key components of the solution included:

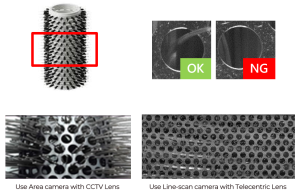

Use Case 1: Quality Check of Hairbrush

- Area Camera with CCTV Lens: This setup allows for a broad and detailed view of the hairbrush surface, capturing high-resolution images necessary for accurate defect detection.

- Line-scan Camera with Telecentric Lens: This configuration provides high precision in inspecting the linear aspects of the hairbrush, ensuring even the smallest defects are identified.

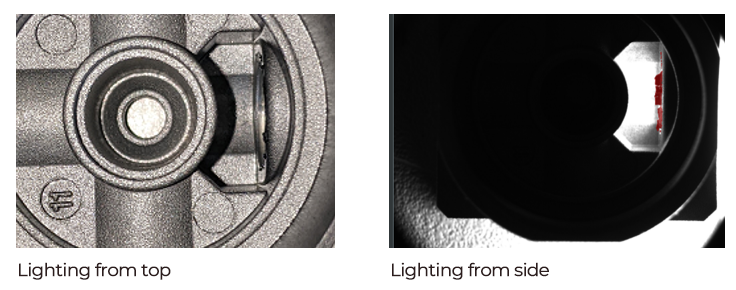

Use Case 2: Burr Detection of Casting Product

- Lighting from the Top: Proper top lighting enhances the visibility of surface features, making it easier to detect burrs on the casting product.

- Lighting from the Side: Side lighting creates shadows and highlights that reveal burrs and other surface irregularities that might be missed with top lighting alone.

By utilizing these specific imaging conditions, the TM AI Cobot’s built-in AI vision system can effectively identify defects in hairbrushes and detect burrs in casting products, ensuring high-quality standards.

Results: The implementation of the TM AI Cobot brought significant improvements to the client’s quality inspection process:

- Increased Accuracy: The tailored imaging setups ensured that the AI vision system could detect even the smallest defects with high precision.

- Enhanced Efficiency: Automation reduced the need for manual inspection, speeding up the quality check process and increasing throughput.

- Reduced Errors: Consistent and accurate defect detection minimized the occurrence of missed defects and false positives, improving product quality.

- Cost Savings: Automation reduced labor costs and decreased the need for rework, leading to significant cost savings.

The successful implementation of TM AI Cobot for automated optical inspection demonstrates the transformative impact of AI and robotics in manufacturing. By addressing the challenges of consistent and accurate quality inspection, Techman Robot has empowered the client to achieve higher standards of quality and productivity, setting a new benchmark in the consumer electronics industry.