Client: A leading manufacturer of handcrafted sleeve components

Application: Automated defect detection for screen-printed metal castings

Challenge:

The client specializes in producing high-quality sleeve components that are distinguished by their unique screen-printed designs, which are used to differentiate between metric and imperial units. Screen printing is a key branding element, and maintaining its quality is essential. The client encountered several challenges in their manual inspection process, which included:

- Inconsistent Defect Detection: Manual inspection struggled to identify defects such as misaligned prints, overlaps, scratches, and blurriness.

- High Labor Costs: The manual inspection process was labor-intensive and costly.

- Human Error: Variations in inspection results due to human error led to inconsistencies in product quality.

Solution:

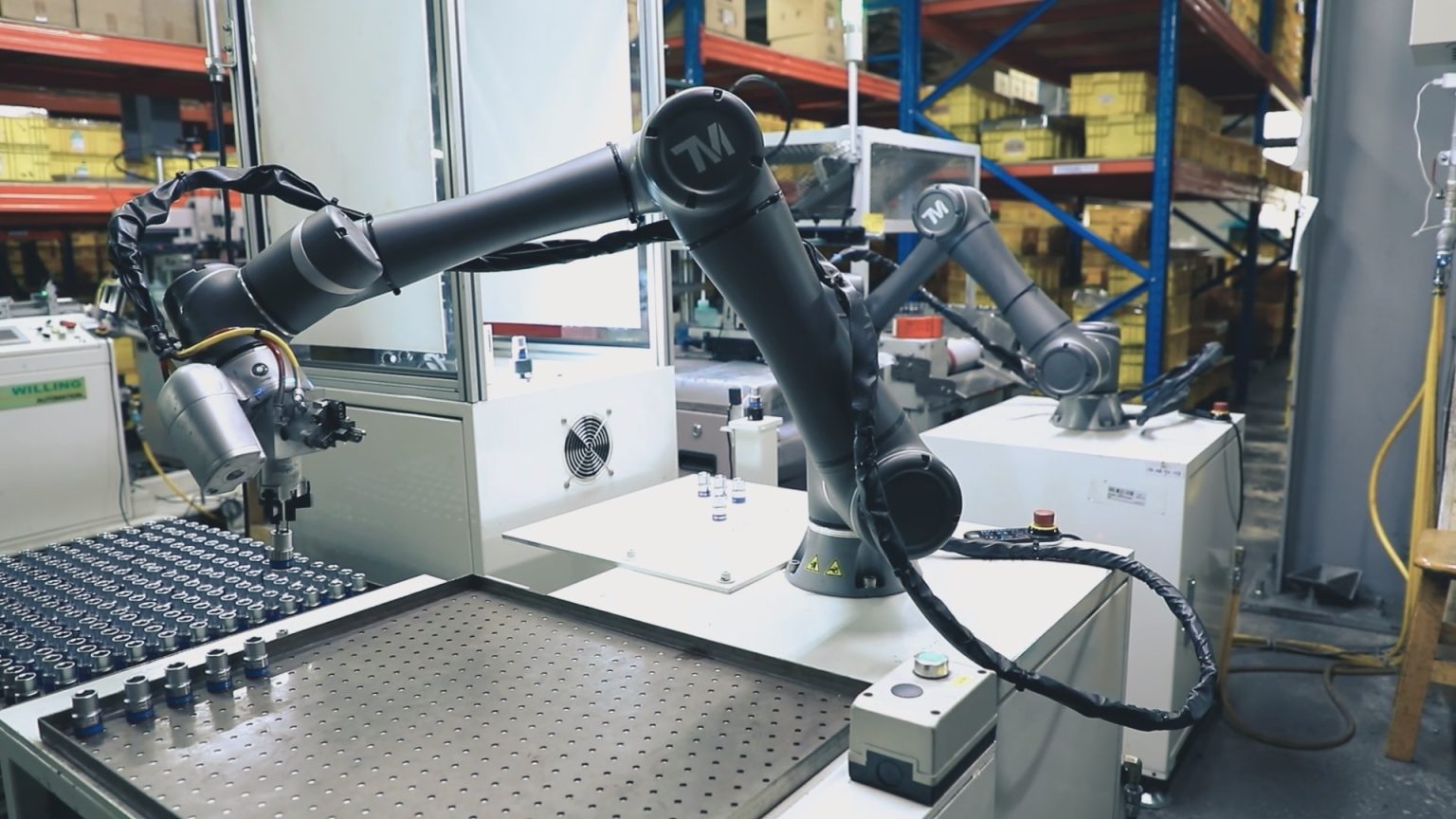

To overcome these challenges, the client implemented an automated inspection line using three TM AI Cobots to perform automated vision inspection. The automation process includes the following components:

- Feeding and Screen Printing: Robotic arms are used to automate the feeding of cylindrical metal castings and their subsequent screen printing. This ensures precision in the placement and alignment of the screen-printed designs.

- Drying Process: After screen printing, the robotic arms automatically transfer the sleeves to a drying station, ensuring consistent drying times and quality.

- AI Inspection: Once the screen printing is complete and the castings are dried, they are imaged using a line-scan camera in conjunction with a rotator. The TM AI Cobot’s built-in vision system then conducts a detailed inspection to detect any defects, including:

- Surface Scratches: Ensuring the surface is free of any damage that could affect the print quality.

- Misalignment: Verifying that the prints are correctly positioned on the sleeve.

- Printing Overlaps: Identifying any issues where screen prints overlap incorrectly.

- Blurred Printing: Detecting areas where the print is not sharp and clear.

Results:

The implementation of the TM AI Cobots significantly enhanced the client’s production process:

- Improved Accuracy: The automated system’s precision in detecting even the smallest defects ensured consistent print quality across all products.

- Increased Efficiency: Automation reduced the reliance on manual labor, accelerating the inspection process and increasing overall throughput.

- Cost Savings: Reducing manual labor and rework due to defects led to significant cost savings for the client.

The successful deployment of TM AI Cobot for automated defect detection in screen-printed metal castings demonstrates the power of AI and robotics in modern manufacturing. Techman Robot’s solution has enabled the client to uphold the high standards of their brand while boosting efficiency and productivity.