Background and Customer Needs

A major player in Japan’s refrigerated and frozen food manufacturing industry, produces a variety of ready-to-eat salads. One critical stage in their packaging process involves top-sealing, where ensuring no food material is caught in the seal is crucial for food safety, freshness, and compliance with hygiene standards.

The customer was facing challenges where food materials were occasionally trapped in the sealing area. This posed risks of leakage, contamination, and customer dissatisfaction. They needed a reliable inspection system that could:

- Detect any food intrusion in the sealed edge of salad packages

- Minimize human error in visual inspection

- Adapt to different forms and colors of food materials

- Be non-intrusive and maintain production efficiency

Challenges

Despite existing visual inspection procedures, several pain points emerged:

- Human Limitation: Manual inspection was inconsistent, especially under fatigue or during high throughput.

- False Negatives: Transparent food materials, such as onions, were difficult to detect visually.

- Traceability Issues: There was no system to verify if each seal had been properly inspected and logged.

These issues emphasized the need for an AI-driven visual inspection system that could automate defect detection without slowing down operations.

Solution

To address these concerns, Toukatsu Foods introduced an AI-powered inspection system using Techman Robot’s collaborative cobot equipped with a built-in vision system.

The solution involved:

- A camera mounted above the conveyor, capturing high-resolution images of each sealed salad package

- An AI classification model trained to detect the presence of foreign materials (e.g., ingredients trapped in the seal)

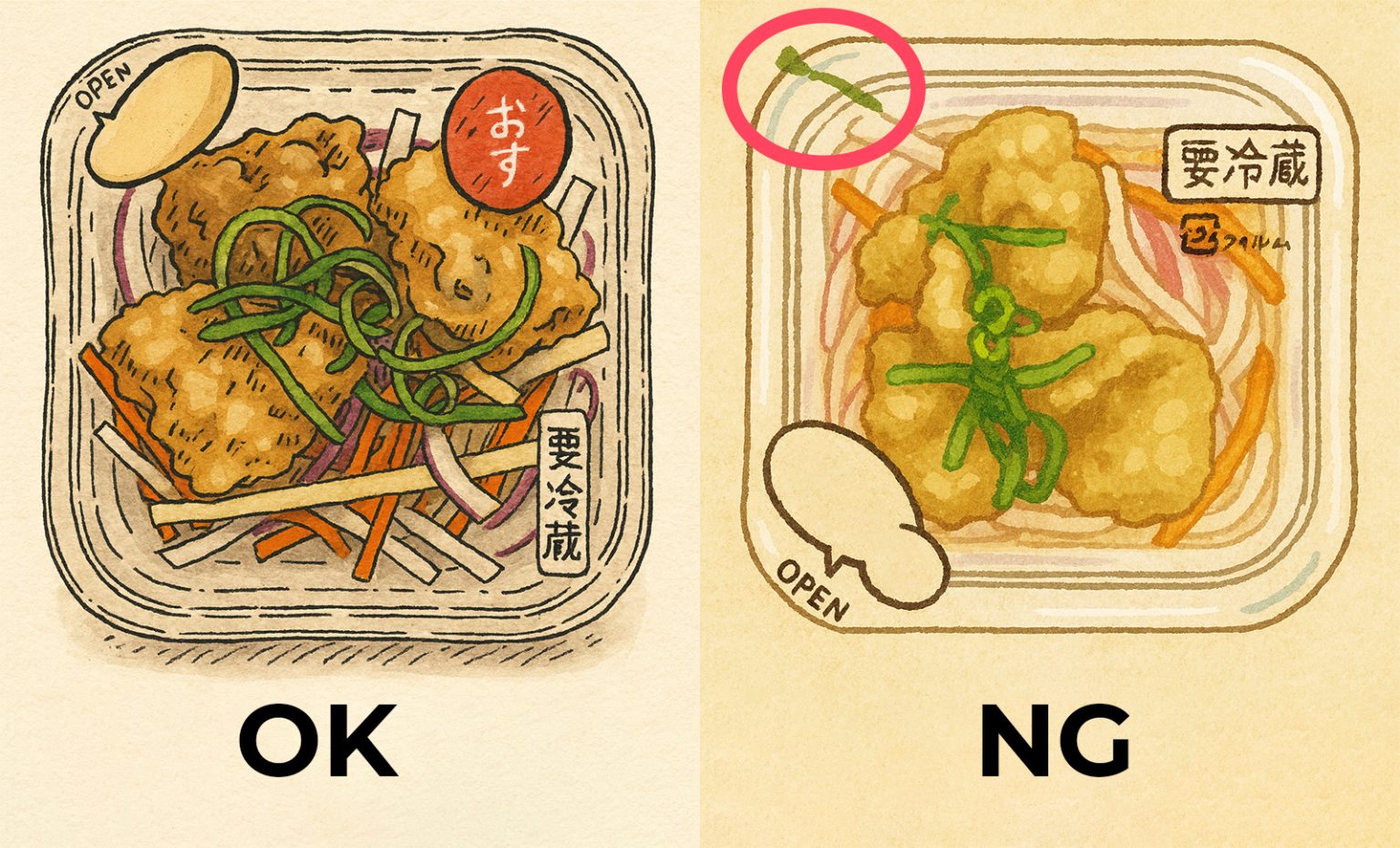

Upon image capture, the AI model instantly evaluated whether any part of the salad intruded into the sealing zone. If detected, the system flagged the package as NG, enabling immediate removal from the line.

AI Model Training

- AI Function Used: Classification

- Dataset Composition:

- OK Images: Sufficient clean images (no food trapped) captured by the manufacturer

- NG Images: Examples food materials trapped in the top-seal

- Preparation Method: Cropping each image into four sealing edges for targeted training

Results & Benefits

- Reduced Human Dependency: Automation minimized fatigue-related errors and ensured inspection consistency across shifts.

- Real-time Sorting: NG products were instantly flagged and removed from the production flow.

- Improved Detection Accuracy: Even transparent items like onions were detected with higher consistency than manual inspection.

- Scalability: The same AI-based logic can be applied to similar food packaging scenarios in the future.

Conclusion

This successful implementation at Toukatsu Foods demonstrates how AI and cobots can transform quality assurance in food manufacturing. By automating the detection of sealing defects, the company not only ensured consumer safety but also streamlined their inspection process—proving the value of intelligent automation in the food industry.