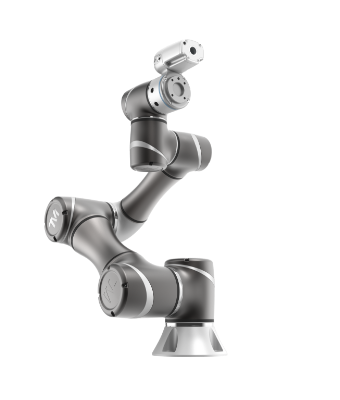

TM5 - 700

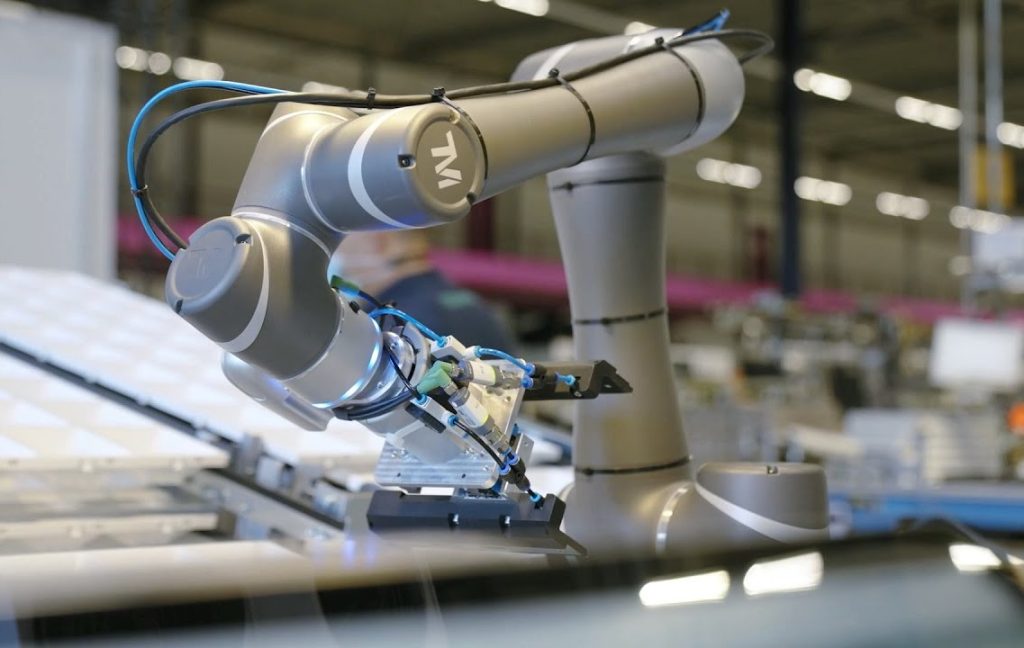

The TM5-700 is our most compact cobot that can be easily integrated into any production line. Designed with a built-in vision system specifically for flexible production needs required by small parts assembly, and production processes in consumer electronics and consumer goods. Our robot offers great versatility for small to medium-sized businesses. TM5-700’s size is also quick to deploy and easy to fit into existing factory environments.

Reach

746 mm

Payload

6 kg

Weight

22.1 kg

2D / 3D Drawing

To download the previous version of the 2D/3D file, please visit the file download center.

Specification

SMART

Future-proof Your Cobot with AI

Benefits of AI Vision

• Automated optical inspection (AOI)

• Quality assurance & consistency

• Increase production efficiency

• Reduce operating costs

AI-powered cobots recognize the presence and orientation of their environment and parts to perform visual inspections and dynamic pick-and-place tasks. Effortlessly apply AI to the production line and increase productivity, decrease costs, and shorten cycle times. AI vision can also read results from machines or test equipment and make appropriate decisions accordingly.

Besides improving automation processes, an AI-driven cobot can track, analyze, and integrate data during production to prevent defects and improve product quality. Easily enhance your factory automation with a complete set of AI technology.

A True Vision Leader

Our collaborative robots are equipped with an integrated vision system, giving cobots the ability to perceive their surroundings which significantly enhances cobot capabilities. Robot vision or the ability to “see” and interpret visual data into command prompts is one of the features that makes us superior. It is a game-changer for accurately performing tasks in dynamic changing workspaces, making operations run smoother, and automation processes more efficiently.

Positioning

Measurement

Identification

AI Inspection

SIMPLE

No experience required

Painless Programming

• Graphical interface for easy programming

• Process-oriented editing workflow

• Simple hand guiding for positions teaching

• Fast visual calibration with calibration board

Designed with first-time users in mind, programming knowledge is not a prerequisite to get started with TM AI Cobot. An intuitive click-and-drag motion using our TMflow programming software reduces the complexity. Our patented technology allows operators with no coding experience to program a project as short as five minutes.

SAFE

Collaborative safety is our priority

No fencing? No worries

• Complies with ISO 10218-1:2011 & ISO/TS 15066:2016

• Collison detection with emergency stop

• Save the cost and space for barriers & fencing

• Set up speed limits in a collaborative workspace

Inherent safety sensors will stop TM AI Cobot when physical contact is detected, minimizing the potential damage for a pressure-free and safe environment. You can also set up speed limits for the robot so it can be used in a variety of environments right next to your workers.