Installation Procedures #

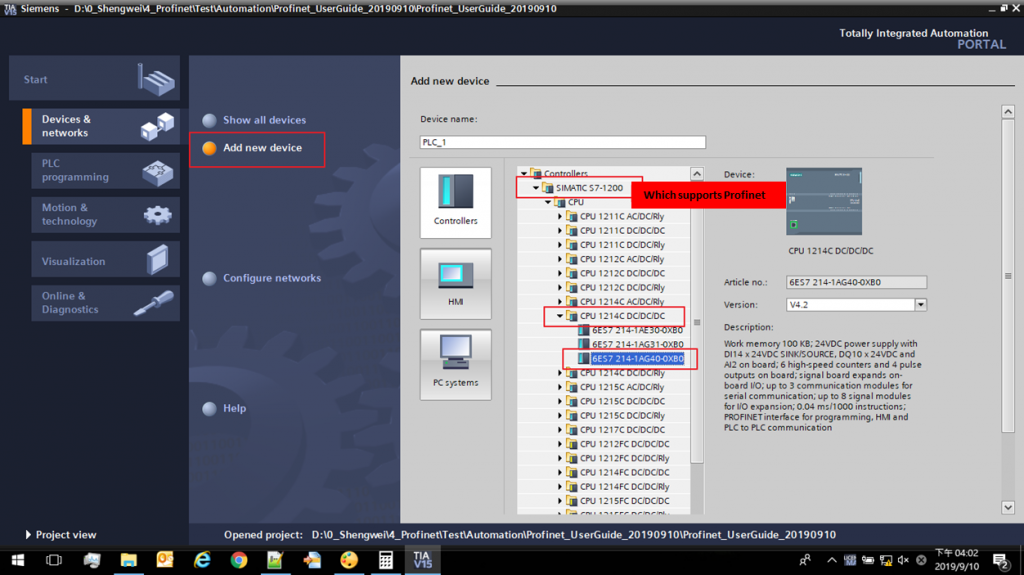

Software: V15

PLC Model: S7-1200 CPU1214 DC/DC/DC || 6ES7 214-1AG40-0XB0

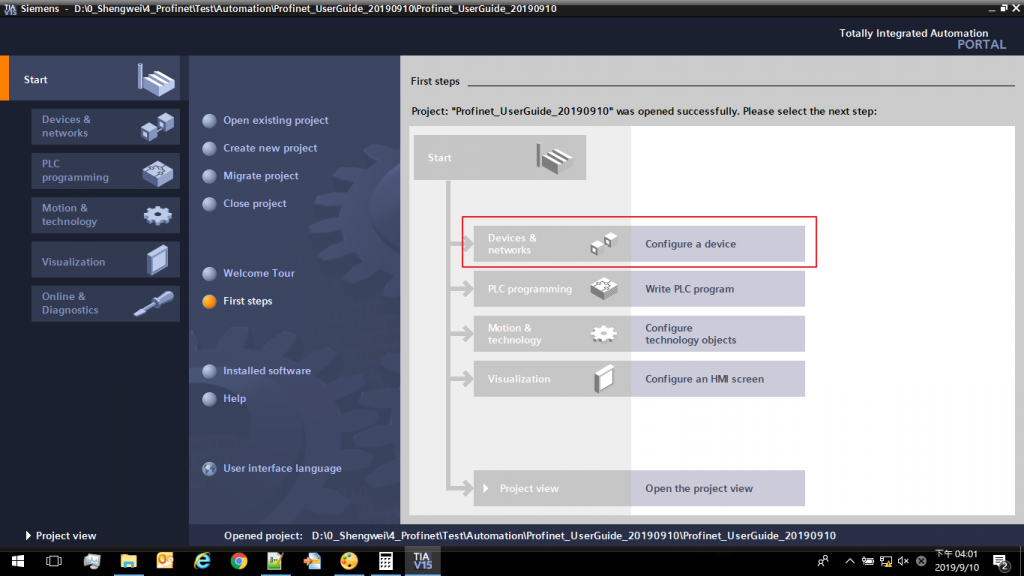

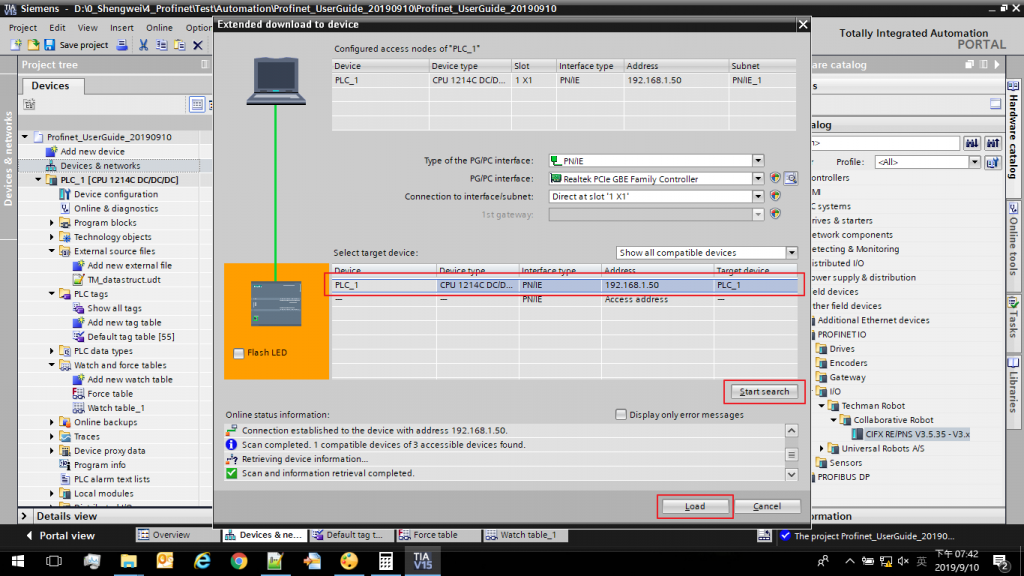

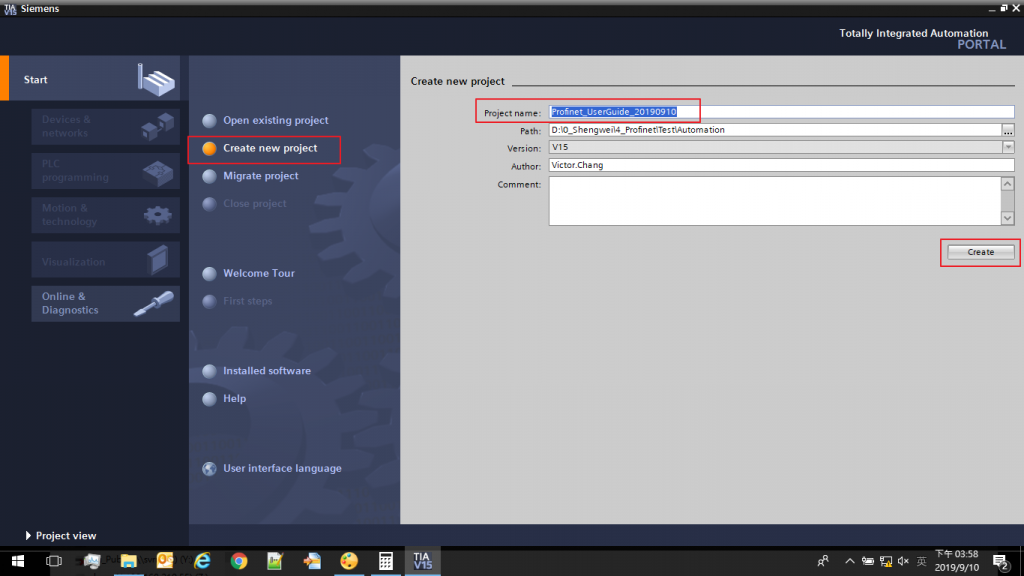

Step #1: Click Start –> Create a new project –> Input a project name –> Create.

Step #3: Click Add new device –> Choose SIMATIC S7-1200 —> Select CPU 1214C DC/DC/DC –> Select 6ES7 214-1AG40-0XB0

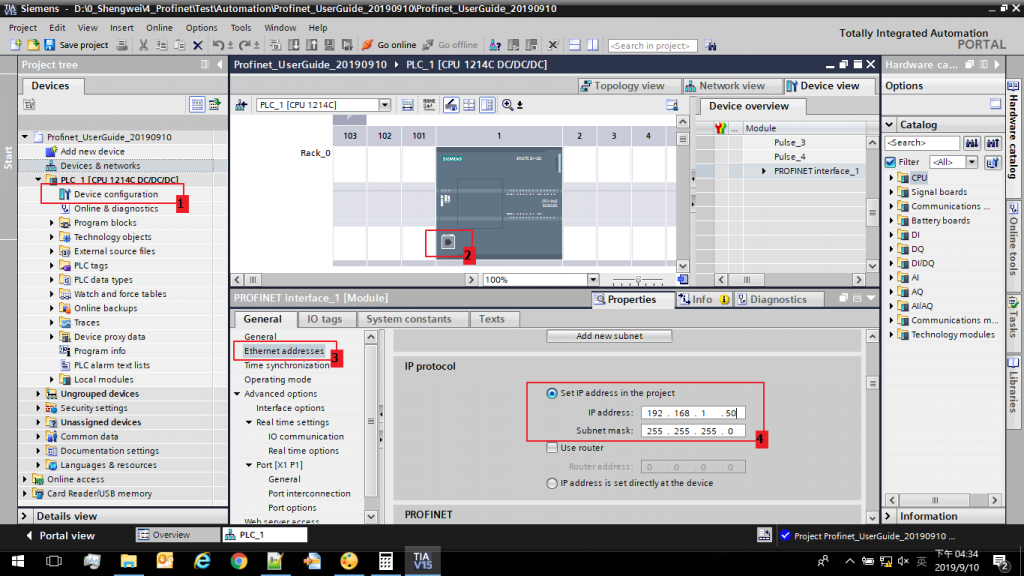

Step #4: Set Controller IP, Find Device configuration –> Click the icon (2) –> Ethernet address –> Set the IP adress

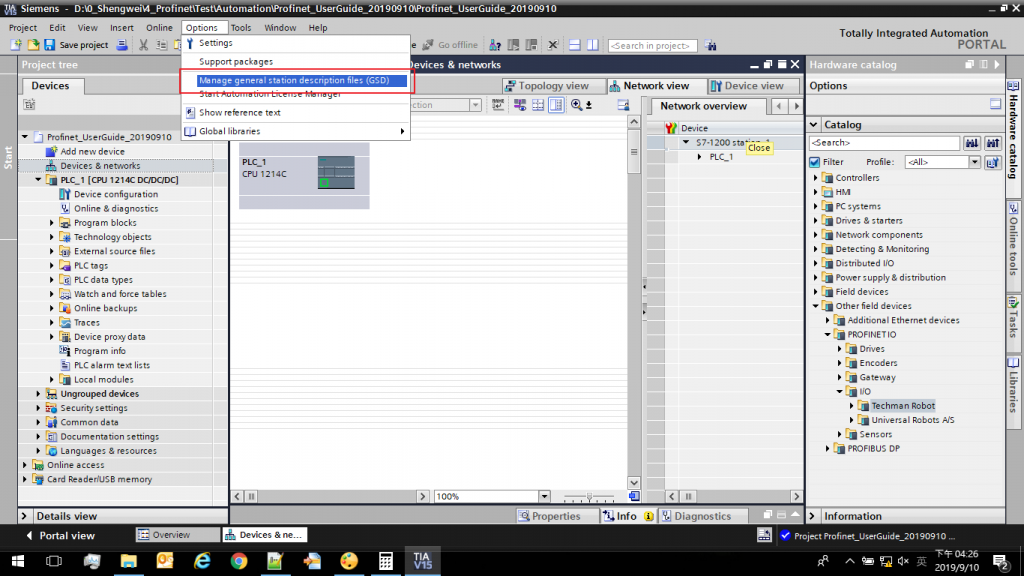

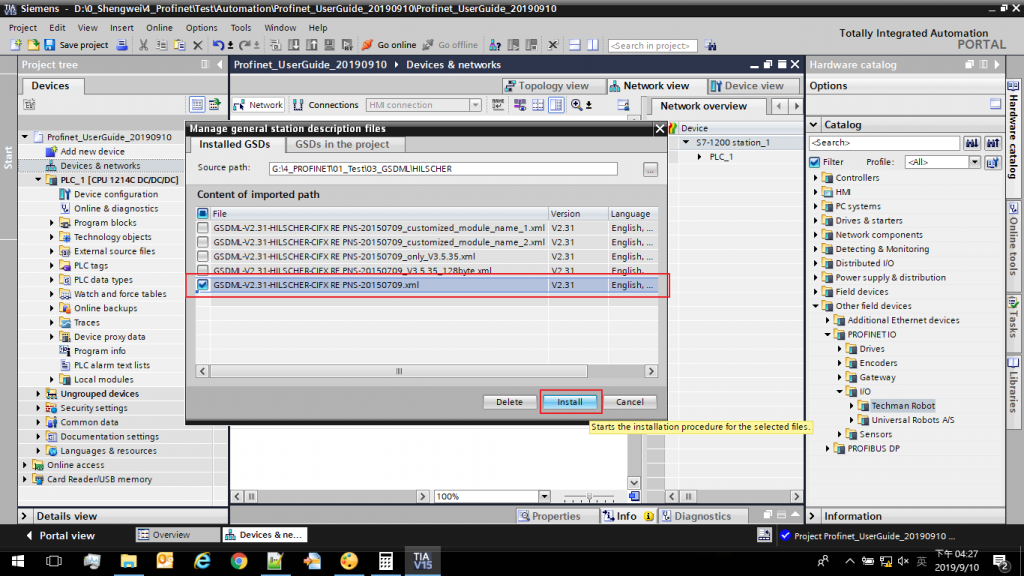

Step #5a: Upload General Station Description Files (GSD.xml) (Please go to TM Download Center to download the Profinet Setting Package)

Click Options –> Manage general station desctiption files

The GSD file is a master file containing device data via PROFINET. After upload the GSD file, than the PROFINET IO device (robot) will show up in the catalog.

Step #5b: Browse the .gds file and click Install.

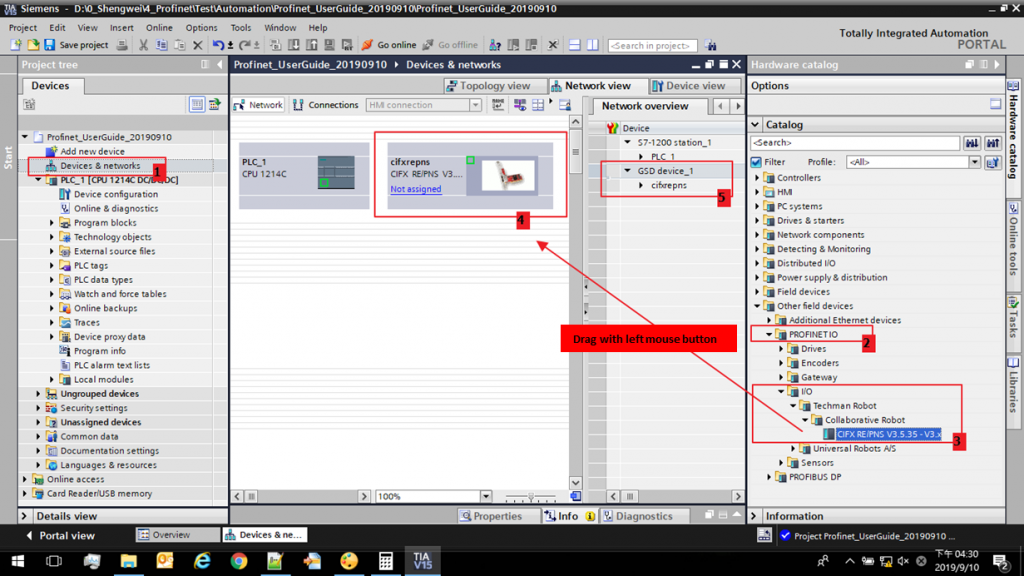

Step #6: Add a PROFINET IO device (robot) module

Devices & networks –> PROFINET IO –> CFIX RE/PNS V3 –> Drag to the red box numbered with 4 –> Check if the module is created successfully

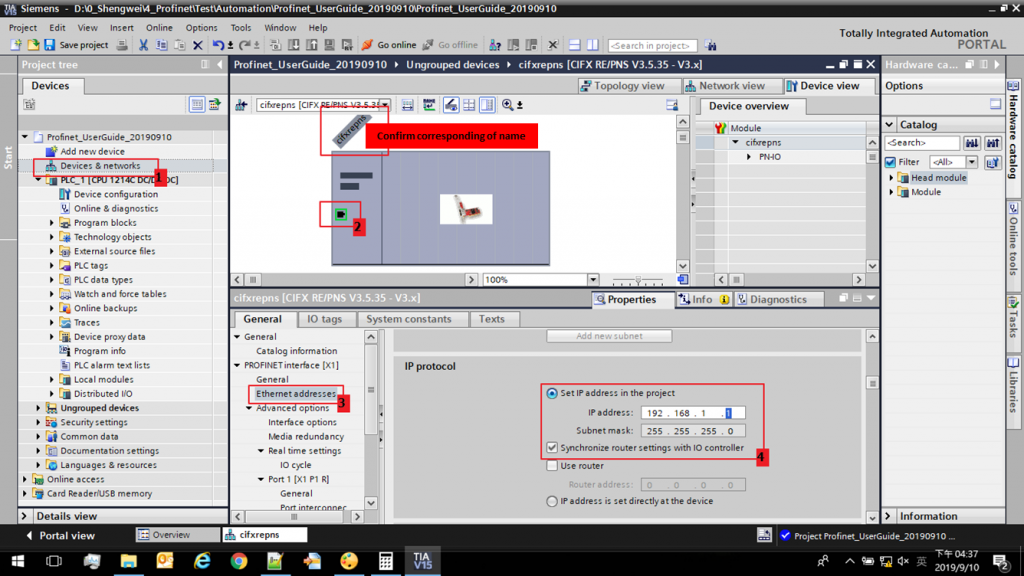

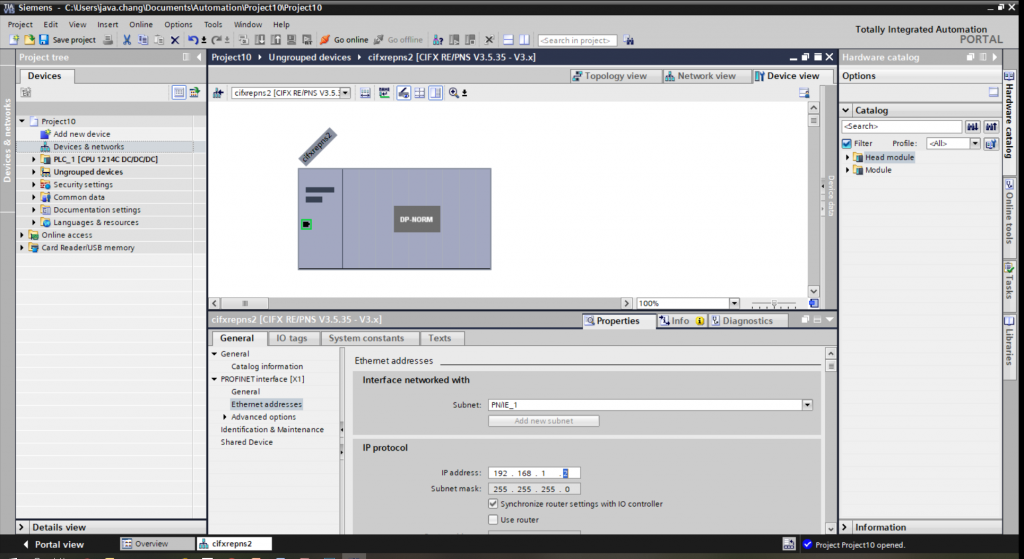

Step #7: Set PROFINET IO device (robot) IP

Devices & networks –> Click on the red box numbered with 2 –> Check module name –> Find Ethernet addresses –> Set IP address for the Profinet IO device

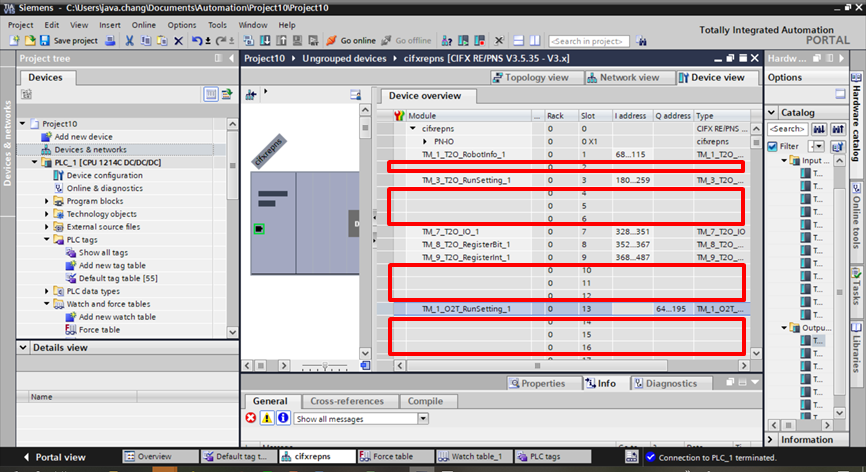

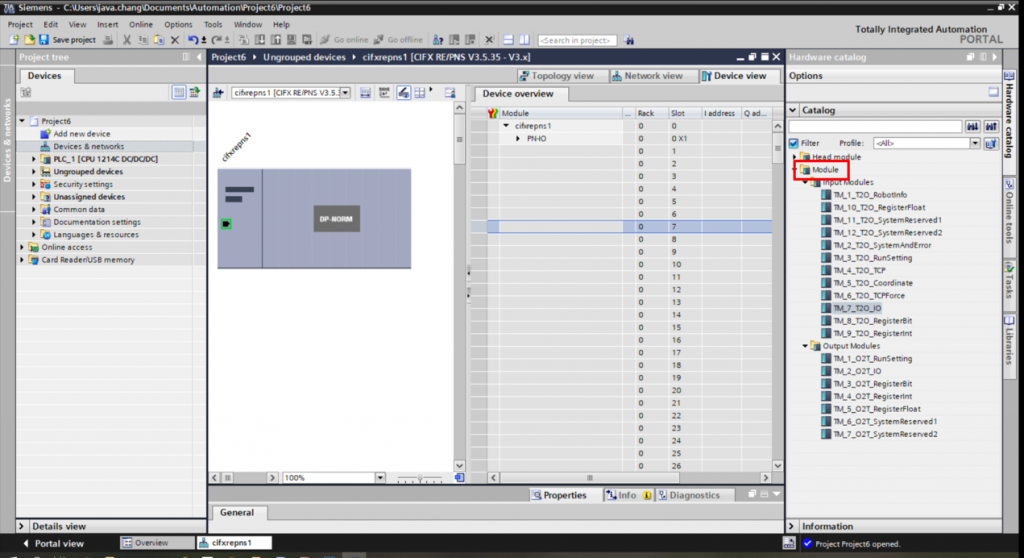

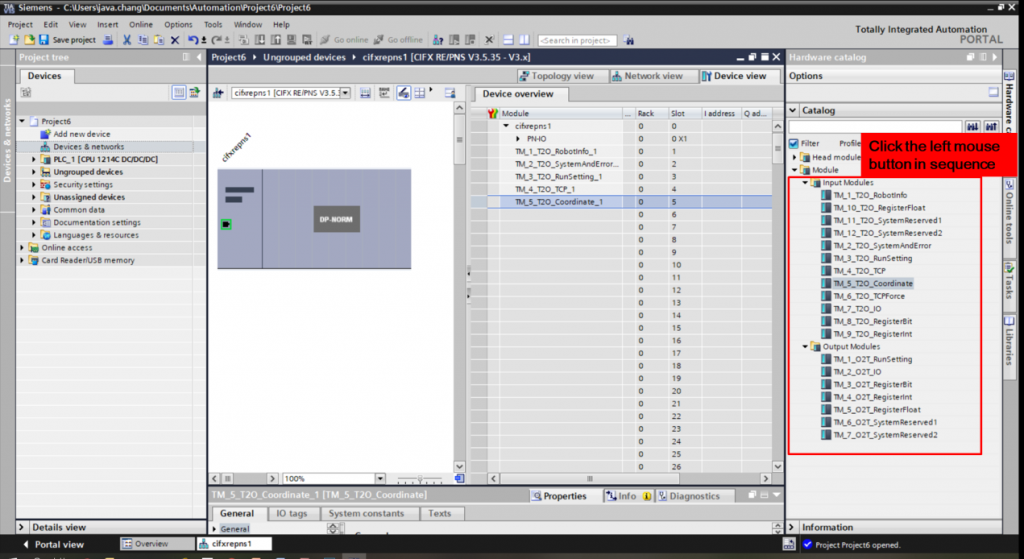

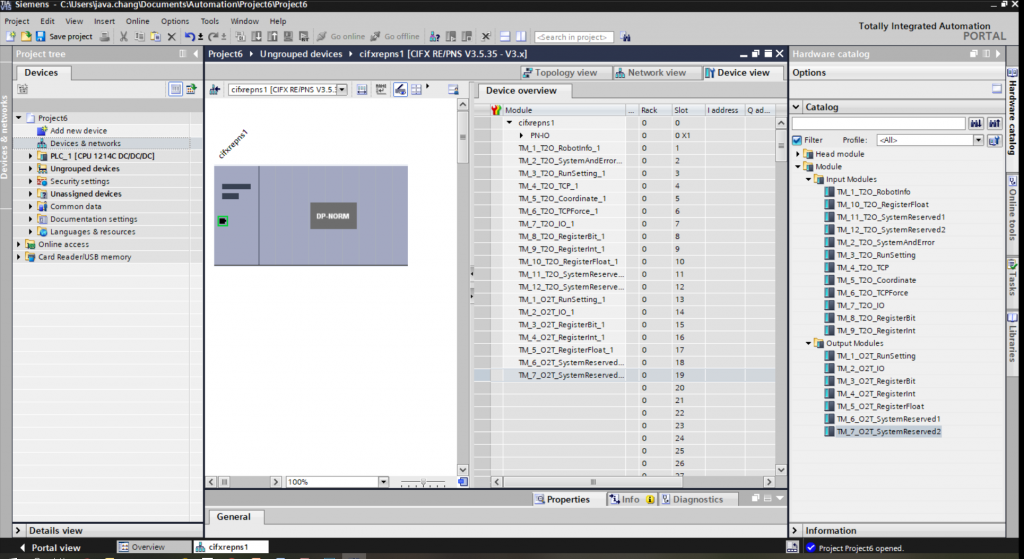

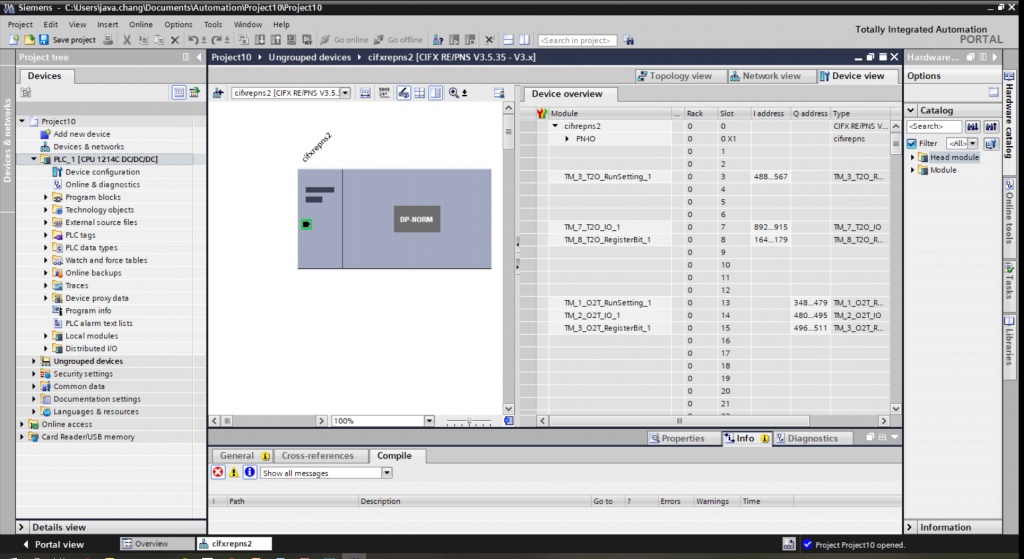

Step #8: Setting PROFINET IO device (robot) Input/ Output Modules

Because the storage space in the PLC is limited, if one PLC wants to control more than one robot, some modules must be discarded. (Module definition is attached in the appendix)

Step #8a: [Only one robot involved] Drag all the modules from the catalog to the PROFINET IO device (robot)

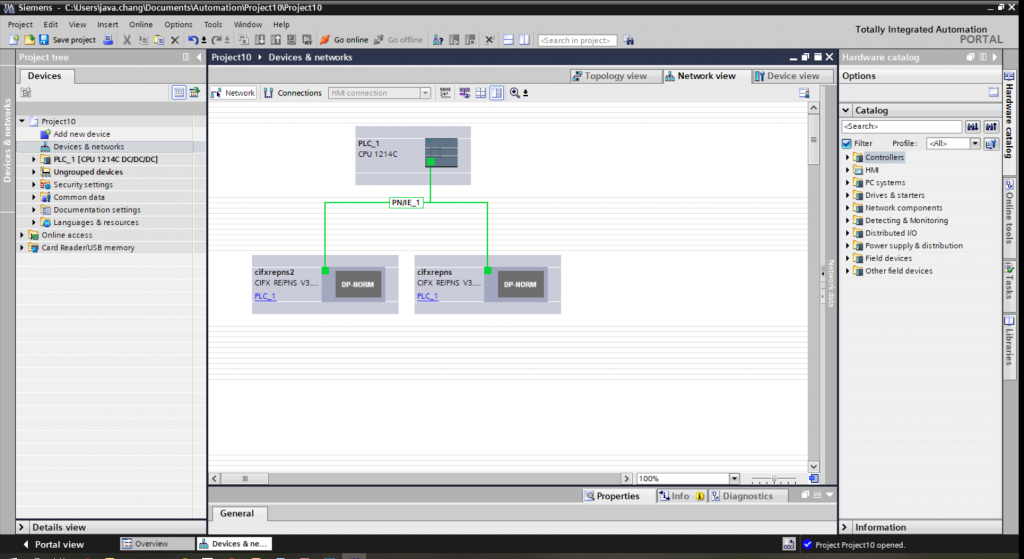

Step #8b-1: [Two robots involved] Add another PROFINET IO device (robot) module and put a name which is different from the first PROFINET IO device (robot).

Step #8b-2: Give the second PROFINET IO device (robot) an IP that is also different from the first PROFINET IO device (robot)

Step #8b-3: Drag all the modules from the catalog to the first PROFINET IO device (robot), and then keep the needed modules and drop the unnecessary modules to reserve space for the second PROFINET IO device (robot)

Note: Users should drag all the modules from the catalog to the PROFINET IO device (robot) in advance than dropping the unnecessary modules.

Step #8b-4: Set the second PROFINET IO device (robot) Input/ Output Modules same as the first PROFINET IO device (robot).

Note: Users don’t need to set the I/O position manually. The software will arrange it after adding or dropping modules automatically.

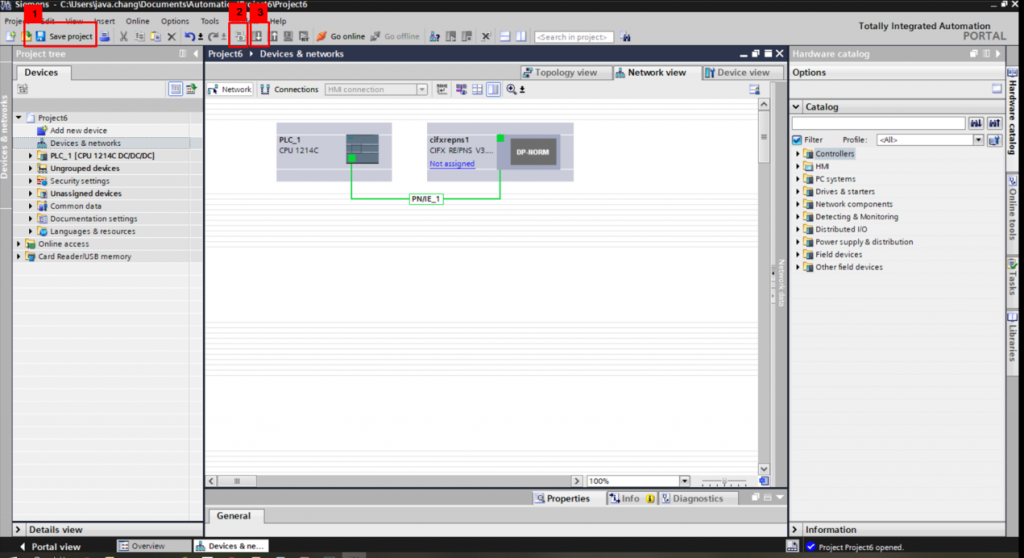

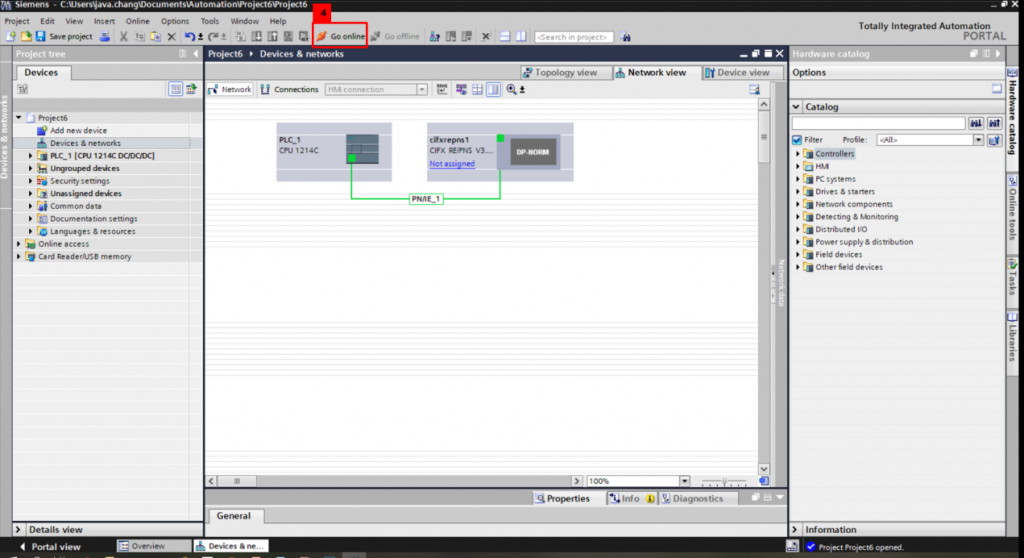

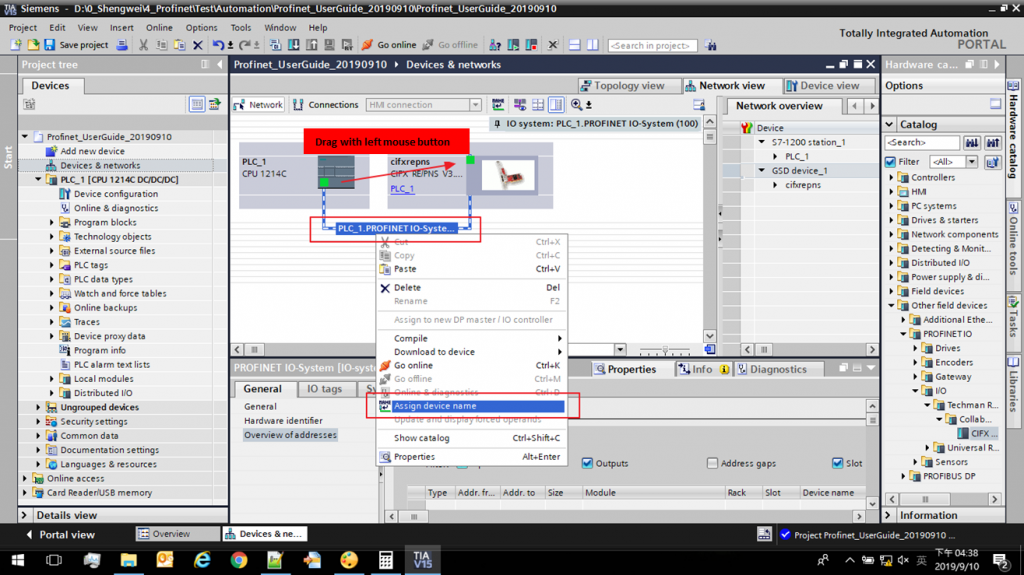

Step #10: Connect PLC Module and PROFINET IO device (robot)

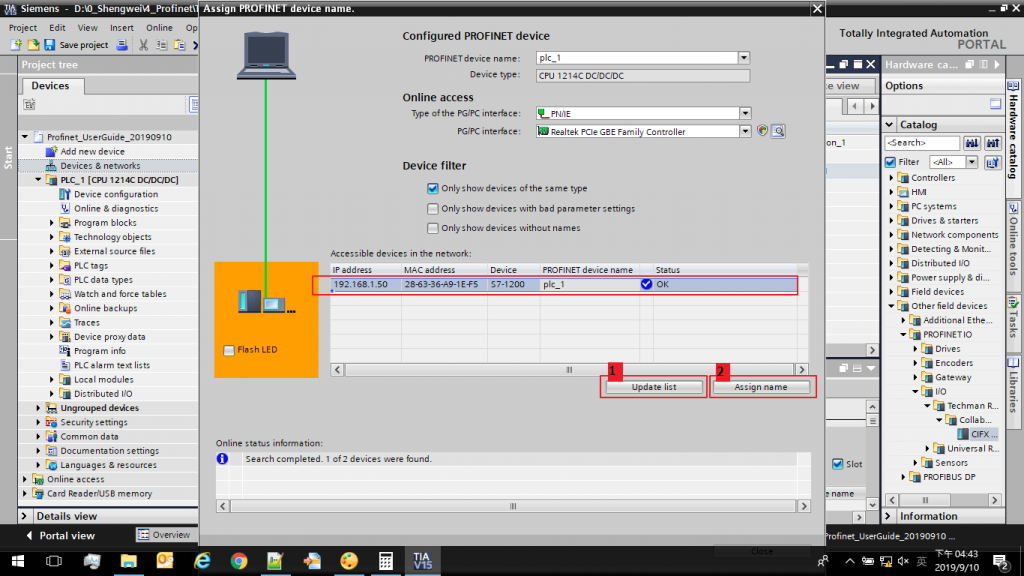

Know-how: To Siemens PLC, the name of the device has priority over its IP. It means PLC will recognize the device’s name first and then its IP.

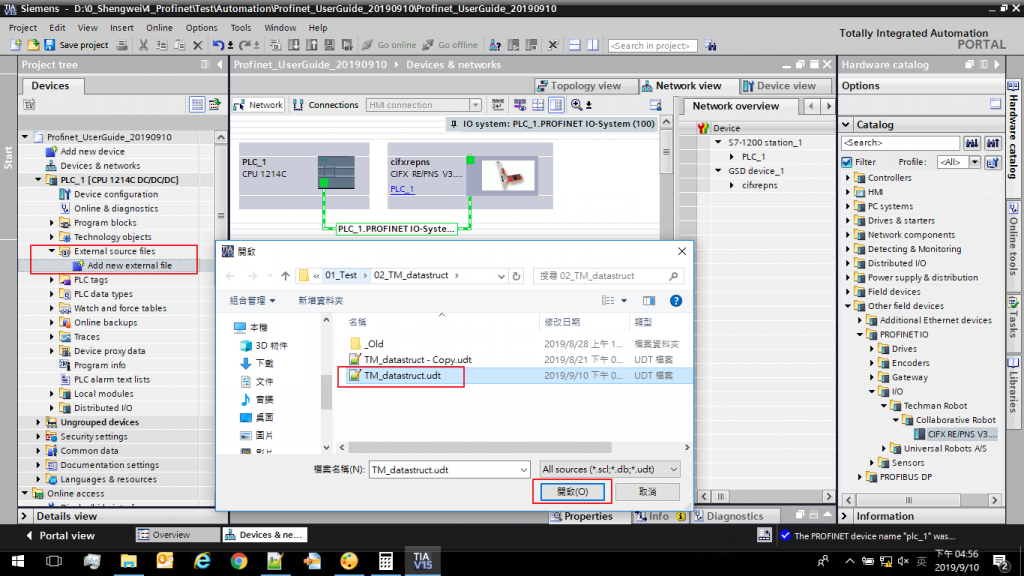

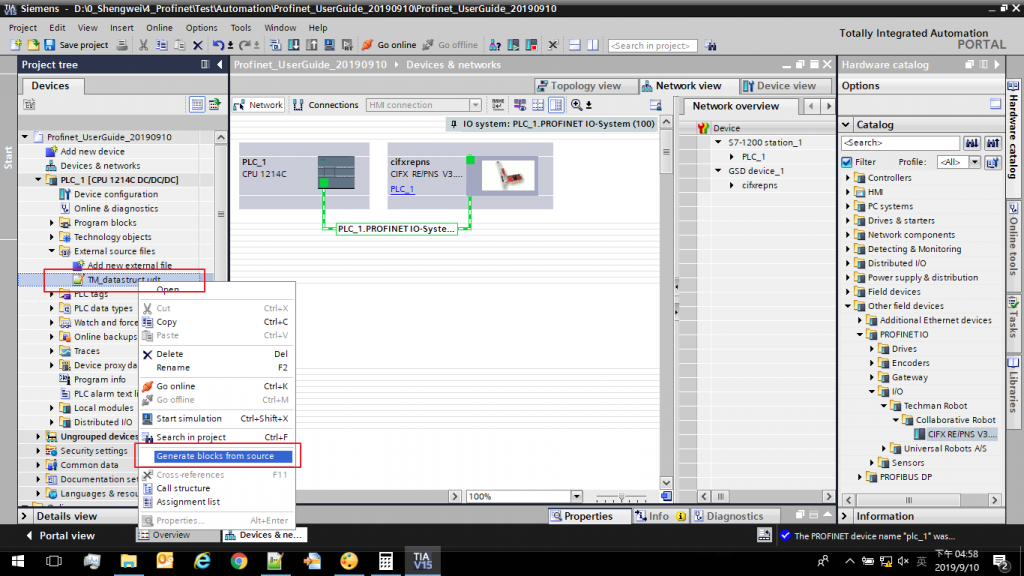

Step #11: Upload User Defined Type Files (*.udt)

User-Defined Data Types (UDT) are commonly used in Programmable Logic Controller Programming in order to group data and maximize code reusability.