Examples are valid for:

TMflow Software version: 2.24 or above

TM Robot Hardware version: HW5.0 or above

Note that older or newer software versions may have different results.

In the fiercely competitive landscapes of electronics and automotive manufacturing, the race for speed and precision has reached a fever pitch. As global manufacturers demand higher Overall Equipment Effectiveness (OEE) and maximized throughput, traditional “stop-and-go” processing is increasingly seen as a hidden bottleneck, dragging down the efficiency of modern production lines.

Eliminating the “Stop-and-Go” Bottleneck

In conventional Automated Optical Inspection (AOI) or processing tasks, a product must come to a complete standstill before a camera can capture an image or a robot can execute a command. While a two-second pause might seem negligible, when multiplied by tens of thousands of cycles per day, the resulting dwell time represents a massive loss in potential capacity.

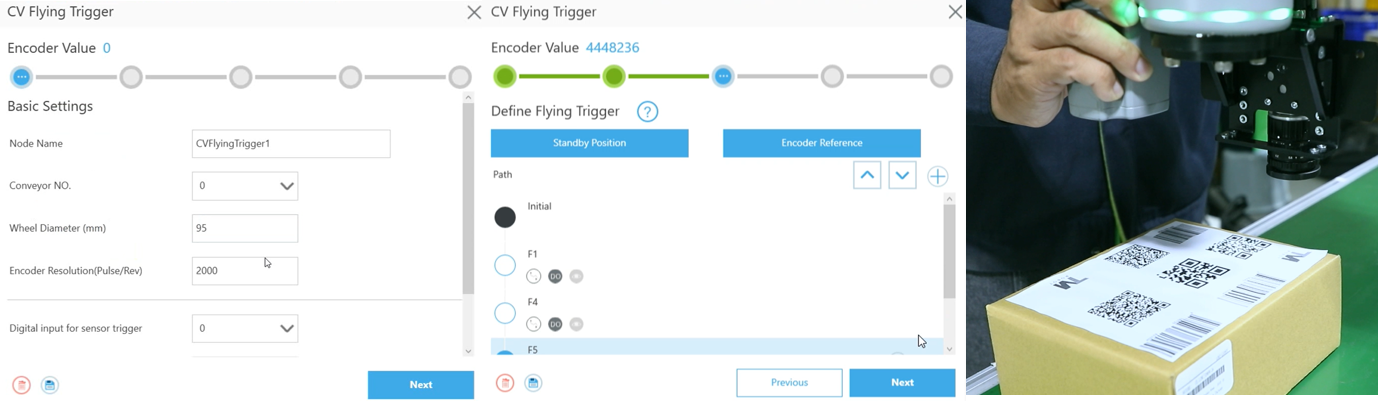

Building on the phenomenal success of the Flying Trigger Node introduced in TMflow 2.22, which empowered robots to perceive their environment while in motion, we are now taking a significant step further. We are proud to introduce the CV Flying Trigger Node (Conveyor Flying Trigger).

Tailored for High-Velocity Environments: Application Scenarios

The CV Flying Trigger Node was engineered specifically for industries where every millisecond counts. By allowing the robot to perform inspections or tracking while products keep moving on the track, we redefine the pace of the factory floor:

- Electronics Industry: Achieve high-speed PCB inspection “on the fly.” There is no longer a need for mechanical stoppers or pneumatic cylinders to halt the board, ensuring a continuous, fluid production flow.

- Automotive Industry: Execute real-time serial number identification or glue bead inspection on moving parts. This ensures that the Takt Time is never interrupted, maintaining a constant pulse for the assembly line.

Democratizing Complex Technology: The Guided Wizard

Historically, integrating conveyor synchronization with high-speed flying triggers required specialized engineers to write complex synchronization logic and code. We have eliminated this barrier to entry.

The CV Flying Trigger Node features a new, Guided Wizard that transforms a sophisticated technical setup into a few intuitive steps. From vision calibration to conveyor speed synchronization, the system handles the heavy lifting in the background. This allows users to deploy a professional-grade flying trigger AOI system in minutes, rather than days, drastically reducing R&D costs and deployment timelines.

Conclusion: The Ultimate Catalyst for Throughput

The mission of the CV Flying Trigger Node is clear: to effectively eliminate processing dead time and dramatically boost your total throughput. When a robot no longer needs to wait for the world to stop, and when “cognition” and “motion” are perfectly synchronized, your production line achieves a new level of aesthetic and functional fluidity. This is our promise to the future of manufacturing: a world where production never stops, and intelligence is always in motion.