Examples are valid for:

TMflow Software version: All versions with Force Control Node.

TM Robot Hardware version: All versions.

Other specific requirements: Force sensor needed.

Note that older or newer software versions may have different results.

Background Information #

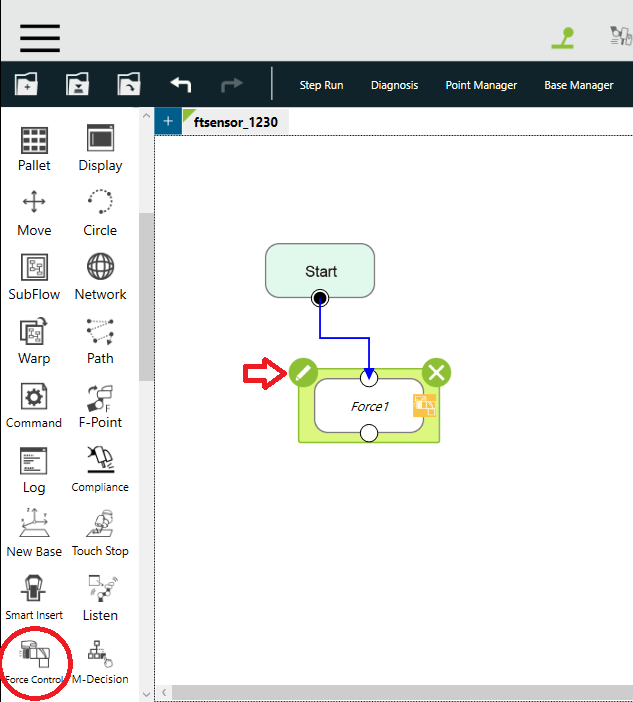

This article will demonstrate an example of using force control node to assist material insert application. In this example, we use force sensor to detect the resist force from different direction while inserting, then Force Control Node will adjust robot posture according to the force detected. Users could try this method if they have difficulties to perform robot material insert straight in to the bottom.

Please be aware, a TM supported Force sensor is needed to use Force Control Node.

Parameter Setting #

Parameter adjustment video illustration:

| Step5 | |

| Step6.1 drag to left | |

| Step6.2 drag to right |

Test Result #

The tool used is the cylinder with diameter of 7mm, and the hole going to insert into is 8mm in diameter.

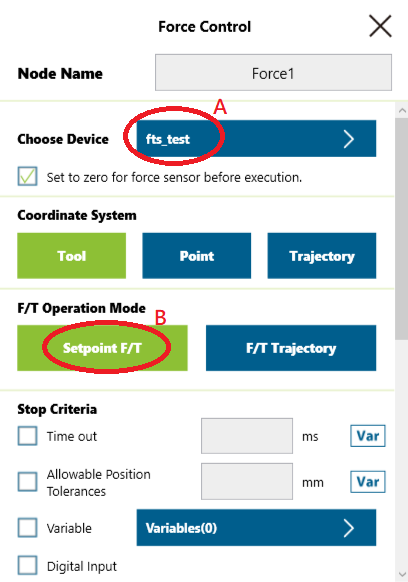

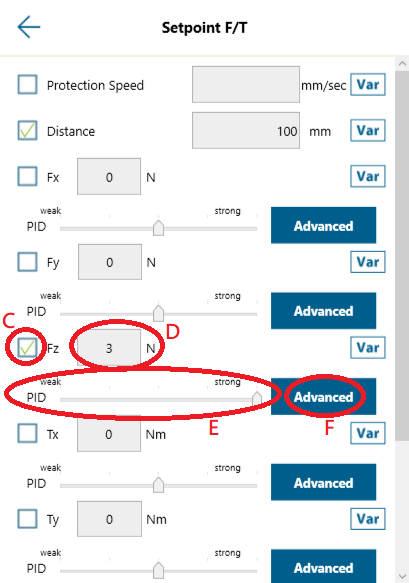

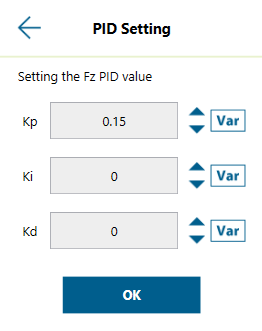

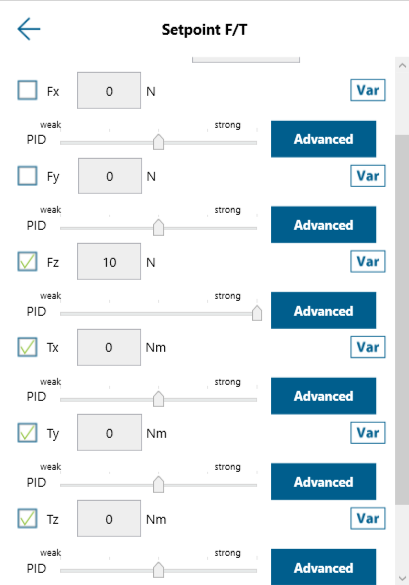

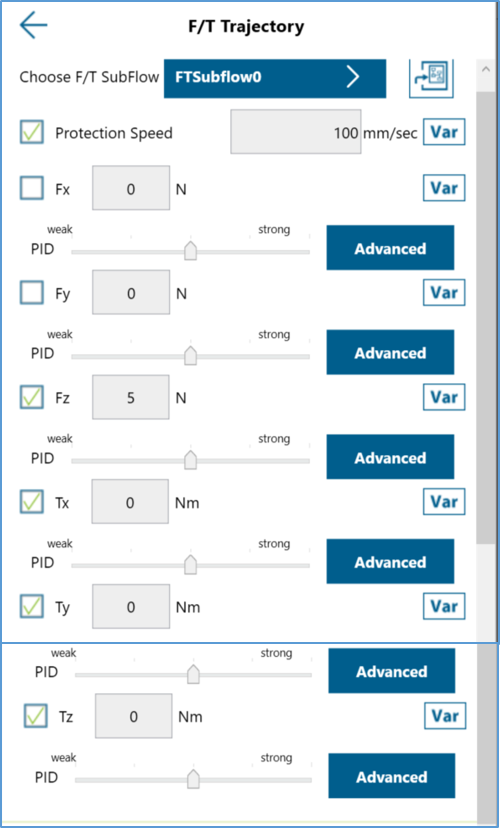

The setting of Force Control Node is as below.

I checked Fz, Tx Ty and Tz because I expect the insert movement will be facing resistance force from those direction, users could adjust according to your scenario.

With 5 degree offset in Rx direction, Force Control Node help robot to insert the cylinder to the hole

If the offset angle is higher, user could try to adjust different parameter combination.

More Example #

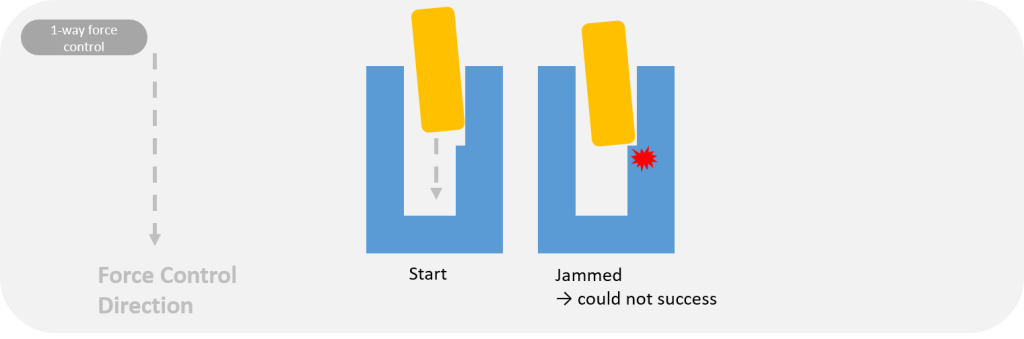

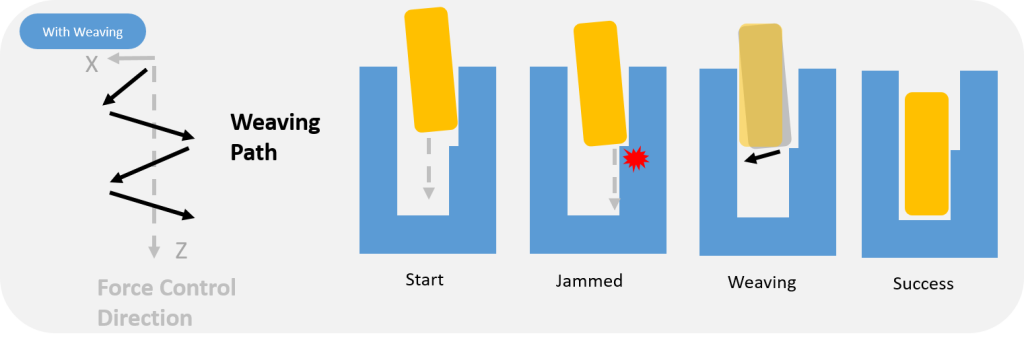

In some corner cases, the object might be jammed.

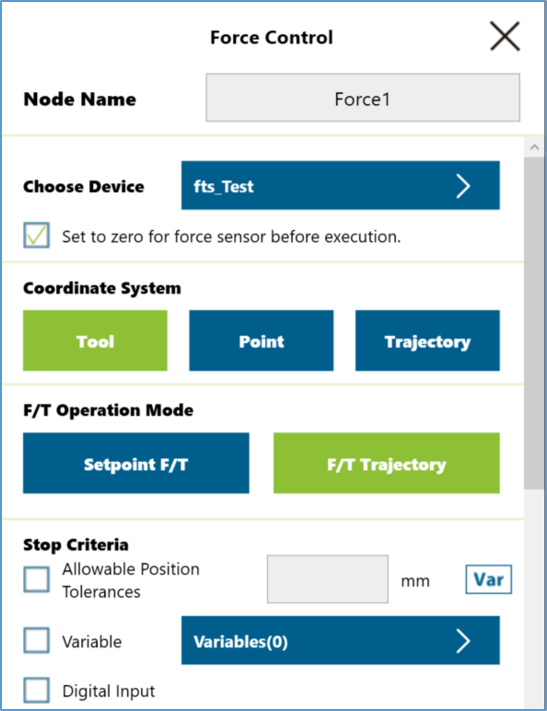

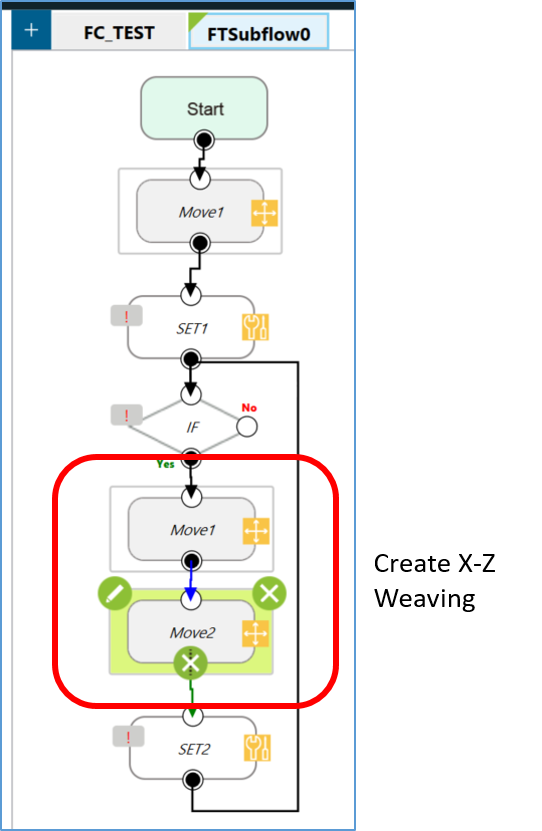

To overcome this issue, weaving could be added to the path of F/T Trajectory mode to create X direction weaving or even X-Y direction weaving.

| 1. Select F/T Trajectory |  |

| 2. Set on the parameter |  |

| 3. Create a F/T Subflow and program it |  |

Result could be seen in below Video

1. If no force control applied, the object will be jammed at the beginning.

2. X direction weaving in dry run

3. X direction weaving in action